Hyundai Plans to Deploy Boston Dynamics’ New Atlas Robot Across its Global Network

Hyundai Motor Group made a surprise announcement at CES 2026 in Las Vegas, disclosing plans to have Boston Dynamics-built robots do important work in automobile manufacturing. Executives laid forth a strategy for spreading humanoid robotics across manufacturing lines, beginning small and building up large.

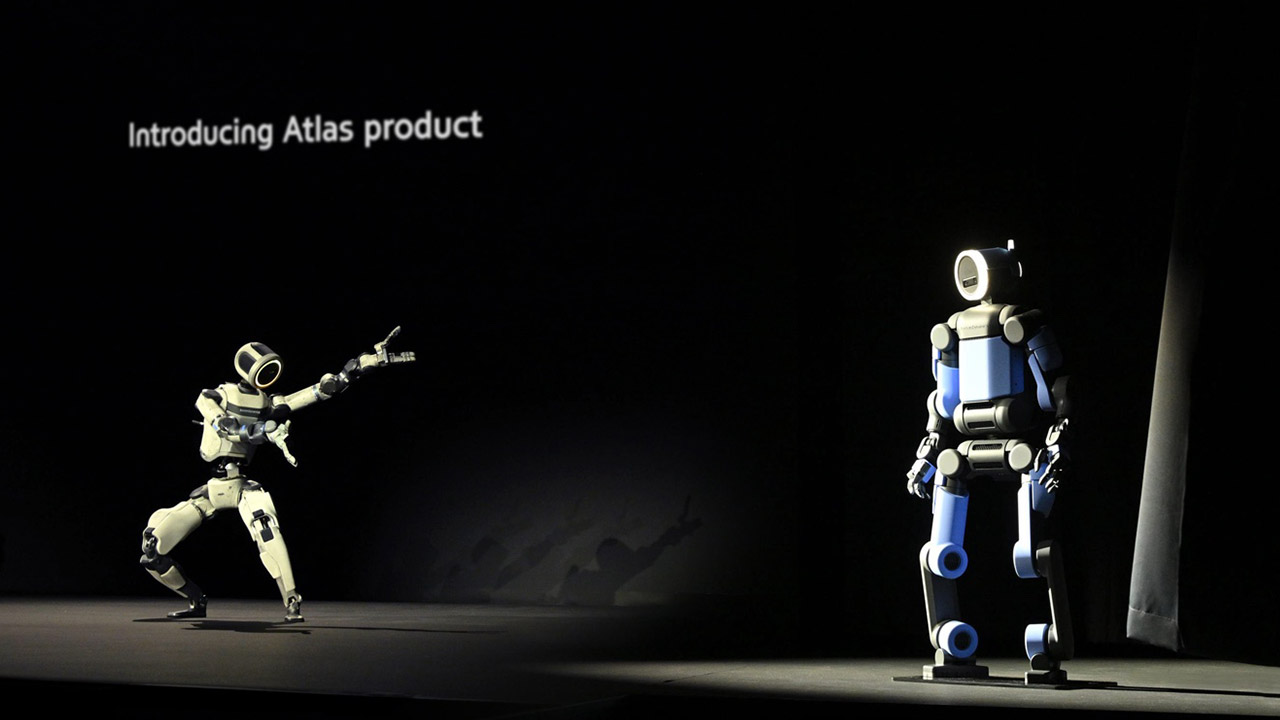

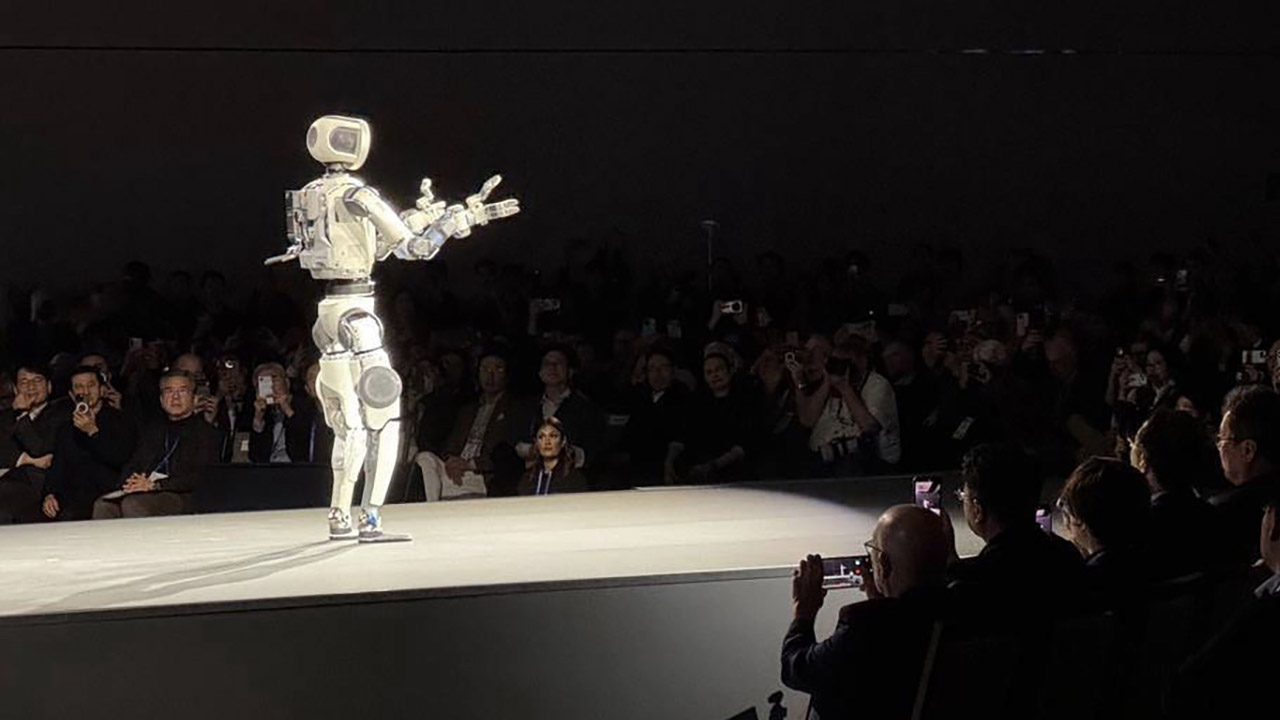

At the center of it all is Boston Dynamics’ brand-new Atlas robot, a completely electric humanoid that recently emerged from Boston Dynamics’ lab. Atlas was built by a team of engineers who gave it 56 joints, the majority of which can spin around in a full circle, and hands equipped with touch sensors to help it obtain a firm grip on objects. The machine can lift large things weighing up to 110 pounds, reach heights of up to 7.5 feet, and, surprisingly, can resist temperatures ranging from freezing cold to burning hot, all while enduring the occasional water splash.

Unitree G1 Humanoid Robot(No Secondary Development)

- Height, width and thickness (standing): 1270x450x200mm Height, width and thickness (folded): 690x450x300mm Weight with battery: approx. 35kg

- Total freedom (joint motor): 23 Freedom of one leg: 6 Waist Freedom: 1 Freedom of one arm: 5

- Maximum knee torque: 90N.m Maximum arm load: 2kg Calf + thigh length: 0.6m Arm arm span: approx. 0.45m Extra large joint movement space Lumbar Z-axis…

Production of the commercial Atlas model began on the same day at Boston Dynamics’ headquarters in Boston, and all units scheduled to ship in 2026 have already been assigned to Hyundai plants and partner sites. Hyundai is taking a cautious approach, evaluating the robots on a process-by-process basis to ensure their reliability before assigning them further responsibilities.

The full-on deployment will begin in 2028 at Hyundai’s Metaplant America in Savannah, Georgia, where the Ioniq 5 and Ioniq 9 are assembled. The early Atlas units are assigned relatively simple tasks, like as transporting parts to particular spots on the production line as needed. Humans will be on hand to keep an eye on things and ensure that the robots are functioning properly, and teaching them a new activity normally takes only a day or two. By 2030, these machines are predicted to be capable of doing more sophisticated tasks such as component assembly.

Behind all of this is a significant increase in production capacity, as Hyundai is building a new robotics factory in the United States, with a portion of a $26 billion capital injection over four years beginning in 2025 going toward it. This new plant is planned to produce 30,000 robot units per year by 2028, meeting demand for tens of thousands of Atlas robots at all Hyundai facilities across the world. A dedicated training center, the Robotics Metaplant Application Center, which will debut in the United States in 2026, will serve as a testing ground for robots before they are transferred to actual production floors.

Hyundai has some key partners on board with this one. Hyundai Mobis, an affiliate, contributes critical actuators and components, while Hyundai Glovis, a logistics arm, manages supply chains. Outside collaborators include NVIDIA, which provides the necessary simulation tools, and Google DeepMind, which lends their experience in sophisticated AI models to offer the robots additional decision-making power.

Other Boston Dynamics innovations have already proven effective in the real world. Spot, the four-legged robot, is keeping an eye on things and gathering data in over 40 nations, including Hyundai sites, while Stretch, the warehouse specialist, has transported an eye-watering 20 million boxes globally since 2023. Atlas builds on their accomplishment and takes it to a whole new level.

Hyundai Plans to Deploy Boston Dynamics’ New Atlas Robot Across its Global Network

#Hyundai #Plans #Deploy #Boston #Dynamics #Atlas #Robot #Global #Network