How Boston Dynamics Took Atlas from Lab Wonder to Factory Floor

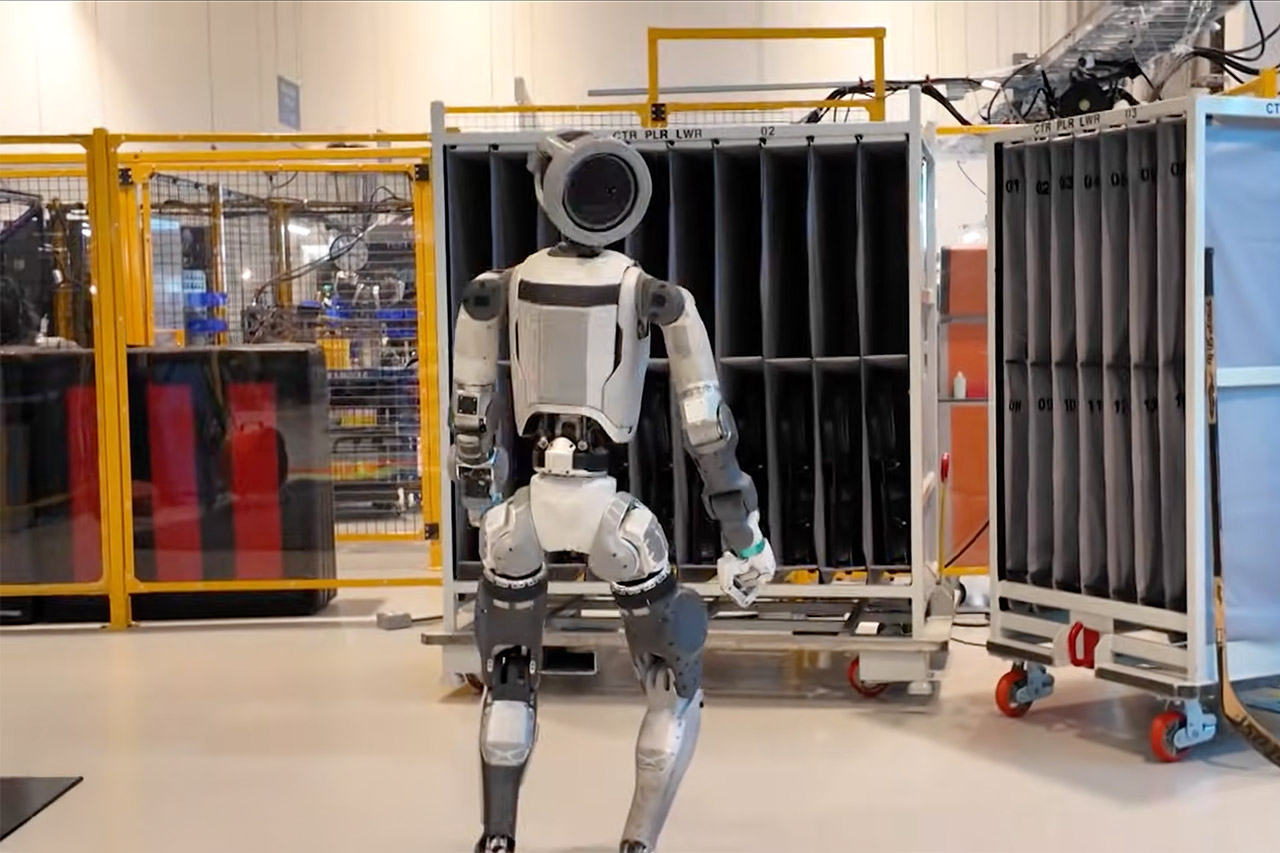

Bill Whitaker walks into the Hyundai auto plant south of Savannah, Georgia and a familiar face is already on the assembly line. Atlas, the Boston Dynamics humanoid robot, is no longer limited to controlled demos. You watch as this 5’9” 200 pound machine takes on real world manufacturing work for the first time.

If you watched 60 Minutes visit Boston Dynamics in 2021 you’ll remember the original Atlas. That first gen model could run, jump and balance itself after being pushed but it was stiff and mechanical. Fast forward to 2026 and Whitaker notes the changes: Atlas moves effortlessly through the exercises, runs like a pro, does flips and even dances the Macarena.

Unitree G1 Humanoid Robot(No Secondary Development)

- Height, width and thickness (standing): 1270x450x200mm Height, width and thickness (folded): 690x450x300mm Weight with battery: approx. 35kg

- Total freedom (joint motor): 23 Freedom of one leg: 6 Waist Freedom: 1 Freedom of one arm: 5

- Maximum knee torque: 90N.m Maximum arm load: 2kg Calf + thigh length: 0.6m Arm arm span: approx. 0.45m Extra large joint movement space Lumbar Z-axis…

Boston Dynamics CEO Robert Playter describes the fundamental concepts that drive this amount of flexibility. His engineers created joints that can turn continuously and without constraint, allowing robots to perform inconceivable jobs. He claims that attempting to create robots that resemble humans will only hinder their progress. Instead, his team is working to create robots that can perform tasks that people cannot.

Scott Kuindersma, head of robotics research, goes into the details during the lab sessions you see. One significant change they made was to keep cables from becoming caught in moving joints, which used to break all the time. Engineers that operate Atlas use VR headsets to remotely direct it, repeating activities such as stacking cups or tying knots until the robot can do it all on its own owing to ultra fast AI chips that can make real-time modifications.

Atlas’ hands feature three fingers and can change shape as necessary. One finger can swing against the others to obtain an extremely tight grip on little things, or they can all spread wide to grasp larger ones. Tactile sensors in the fingertips send pressure input to the neural network, allowing it to decide the appropriate amount of force to apply without crushing or dropping whatever it is holding. Kuindersma compares this to human hands, which can do a variety of activities while maintaining the same basic design but changing and adapting as needed.

Hyundai has owned Boston Dynamics since 2021, which has clearly influenced the project’s direction. The goal now is to put Atlas to the test in real-world industrial settings, such as the Hyundai facility in Savannah, which serves as a proving ground.

How Boston Dynamics Took Atlas from Lab Wonder to Factory Floor

#Boston #Dynamics #Atlas #Lab #Factory #Floor