A Homebrew Rocket Has One Maker Building Thrust with Beer Kegs

Beer kegs should be able to maintain carbonation for weeks due to the pressure they hold. Ryan and his team at Project KegRocket looked at one and immediately imagined something completely different, such as a pair of tanks containing the components for an actual rocket flight. Early on, the team decided to use conventional stainless steel beer kegs as propellant containers because, let’s be honest, they’re a convenient starting point.

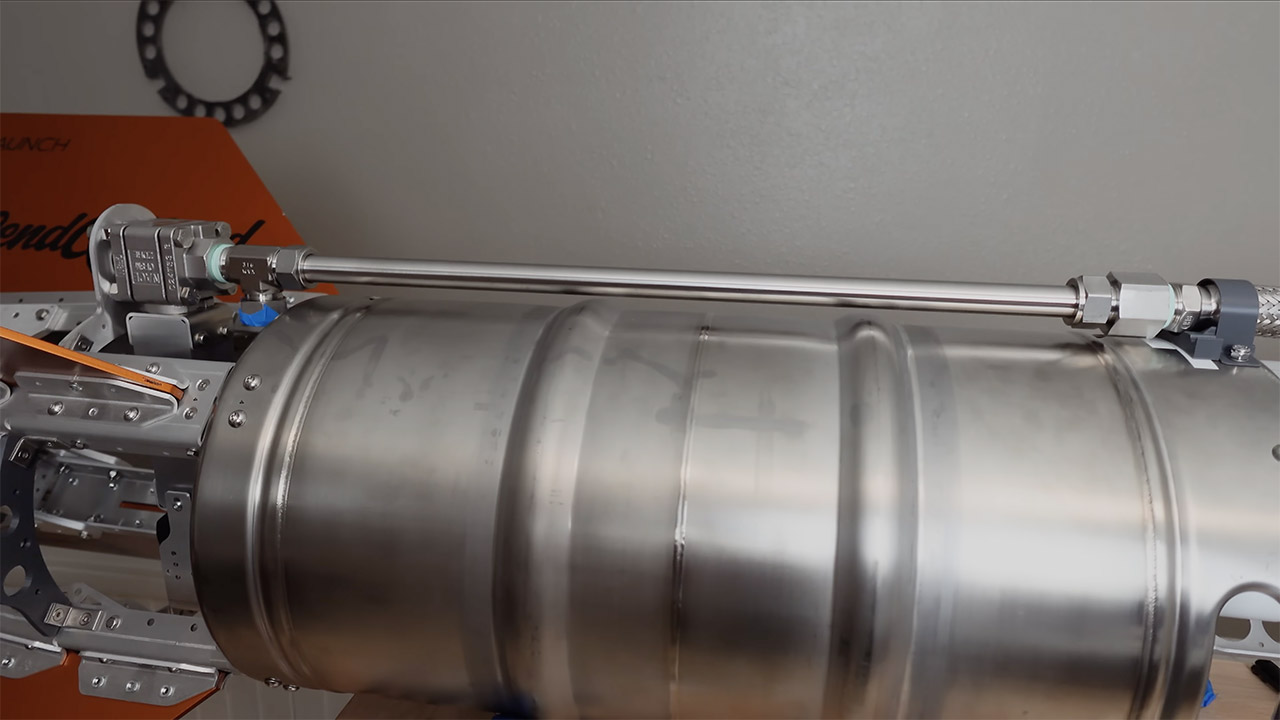

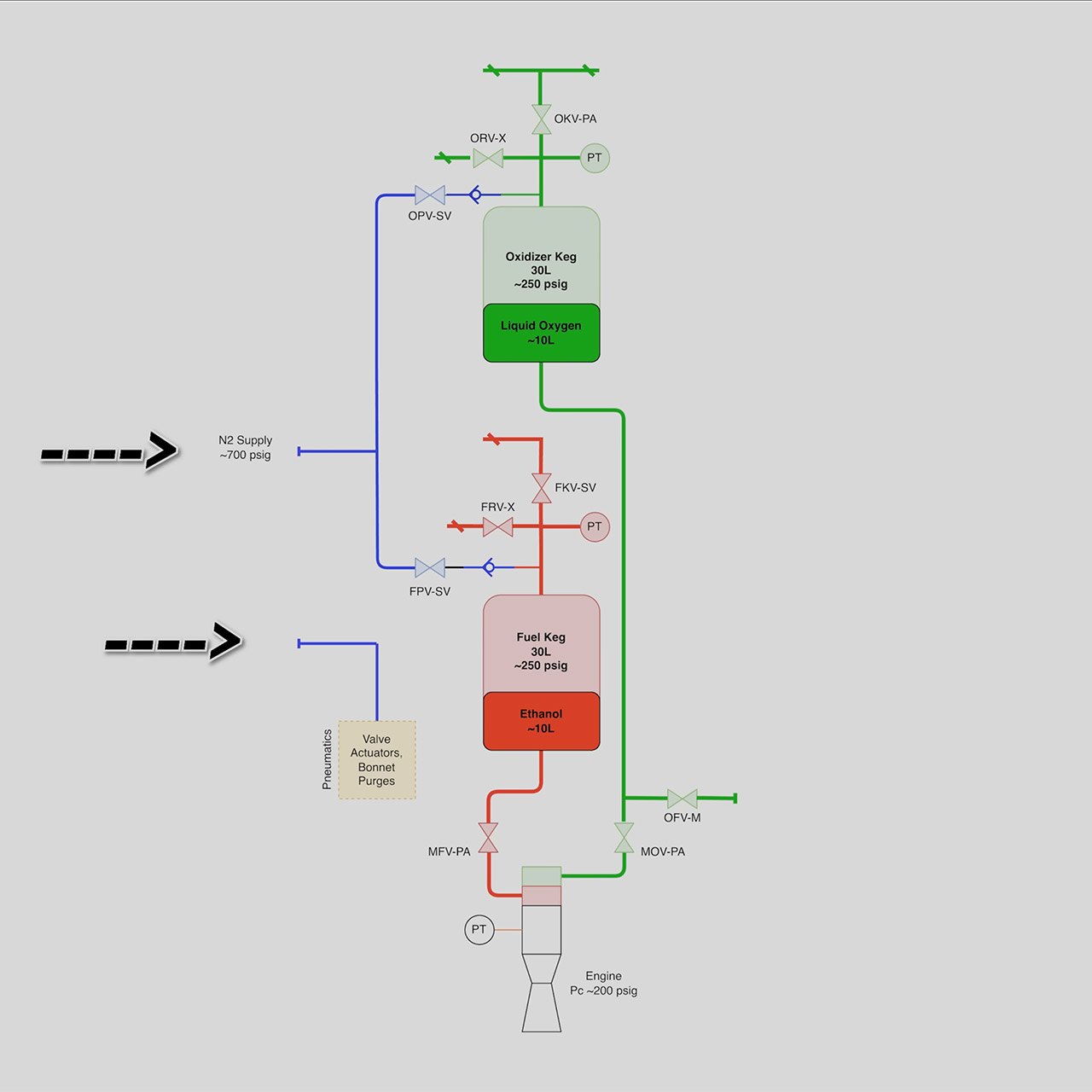

One of the kegs has alcohol as fuel, all pressurized and ready to be pushed into the engine. The second keg contains liquid oxygen, the oxidizer, chilled to cryogenic temperatures. All of the kegs are pre-built to withstand considerably higher pressures than most of us would ever encounter, and their familiar shape is difficult to beat. The ridges along the sides are also flexible enough to withstand minor pressure and temperature changes without issue.

LEGO Technic NASA Artemis Space Launch System Rocket Building Toy for Boys & Girls – STEM Learning &…

- BUILD AN OFFICIAL NASA ROCKET – Kids prepare to explore outer space with the LEGO Technic NASA Artemis Space Launch System Rocket (42221) building…

- 3-STAGE ROCKET SEPARATION – Young builders can turn the hand crank to watch the rocket separate in 3 distinct stages: solid rocket boosters, core…

- STEM BUILDING TOY FOR KIDS – This educational rocket kit was created in collaboration with NASA and ESA to showcase the authentic system that will…

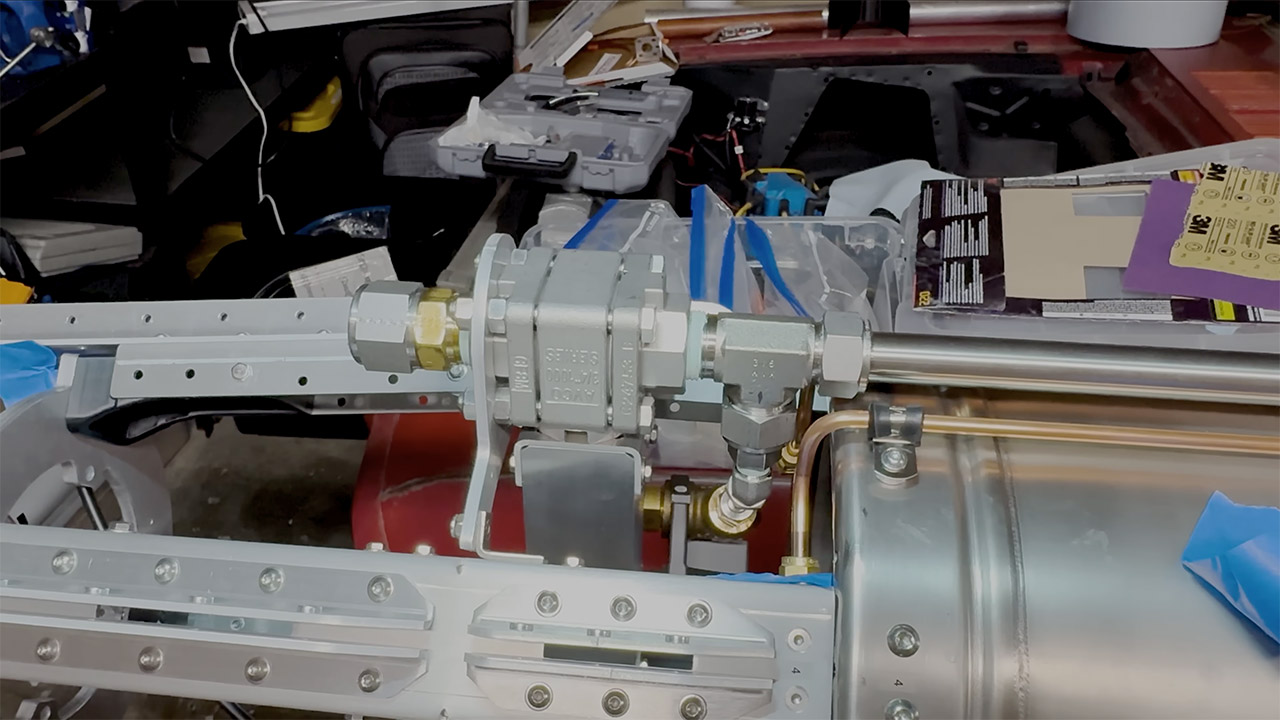

The big issue arises when you have to plumb the entire thing. Liquid oxygen is cold enough to make regular seals brittle and worthless, so rubber O-rings simply fracture when things get hot. And, let’s be honest, pure oxygen isn’t ideal for many materials; they tend to burn or fail. The team used metal-to-metal sealing whenever possible. The plumbing’s backbone consists of double ferrule compression fittings, 37-degree flare connections, and precisely selected NPT threads. Where some flexibility is desirable, stainless tubing can bend slightly as the keg expands under pressure and the LOX boils out.

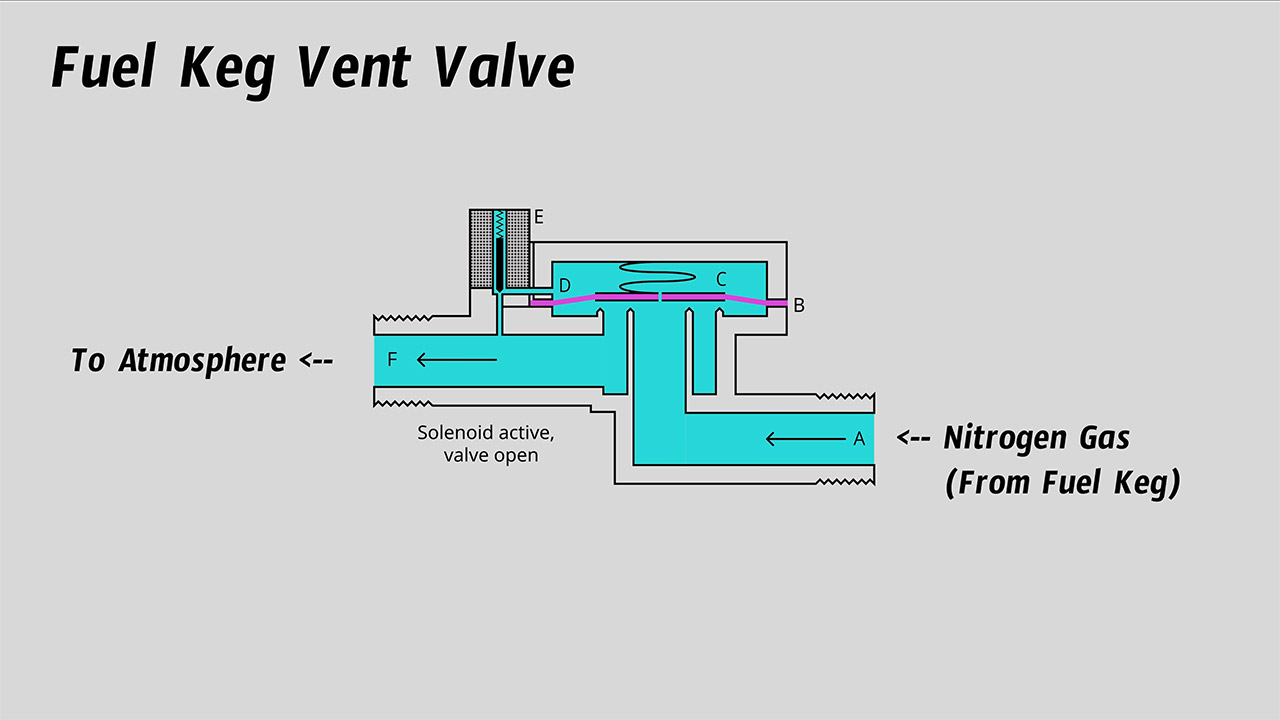

The valves control the flow with precision, while the main oxidizer valve is a large industrial ball valve with a pneumatic actuator, a vented ball design to avoid pressure buildup, live-loaded stem seals, and some fluoropolymer materials capable of handling cryogenic temperatures. The gasoline side uses a standard ball valve from the hardware store, however it does include a unique 3D printed bracket. You have separate valves for filling the oxidizer, venting boil off gasses, and releasing excess pressure via pop valves. Solenoids manage the pressurization using nitrogen, which is fed via umbilicals that detach neatly at launch.

The entire engine is mounted on a bespoke thrust bracket fabricated from steel on a CNC using plans given to JLC. It keeps the plumbing neat and is quite compact. The manifolds are simply carved from aluminum bar stock and route the propellants to the engine in a tidy, pointed configuration. The LOX keg sits on top of the fuel keg, providing some gravity assistance to get things started before pressure takes control.

Safety is clearly at the top of the list, as it should be. The team pressure tested the entire system with nitrogen, checked for leaks with a soap solution, and fixed the one minor one that appeared. To be on the safe side, the crew only goes up to roughly 70% of the kegs’ rating limitations, giving them a comfortable buffer. On the ground, you just need two nitrogen lines: one high-pressure one for tank pressurization and one low-pressure one for valve actuators. When the rocket eventually lifts off, there’s a handy tear-away connector to keep the umbilicals neatly organized.

This approach takes a simple hardware design and adds a creative engineering twist. The kegs serve as sturdy tanks, making it a viable solution that did not require custom manufacturing. Meanwhile, the plumbing system deals with the severe cold of cryogenic temperatures as well as the difficult task of dealing with oxygen that has shown to be as reactive as it has. Earlier episodes on the channel showed the project progressing from basic concept to setbacks, and of course the usual suspects, integrating the avionics with the help of some partners, and carrying out smaller-scale testing such as a liquid motor up in an airframe.

The fluid system has just completed its pressure and leak checks, and if things continue as planned, a static fire will be the next important step, followed by the full launch that the crew has been aiming for since the beginning.

[Source]

A Homebrew Rocket Has One Maker Building Thrust with Beer Kegs

#Homebrew #Rocket #Maker #Building #Thrust #Beer #Kegs