Ancient Egypt’s Mastery of Flat Surfaces is a Masterclass in Precision Without the Mystery

The ancient Egyptians were able to accomplish some incredible feats in flatness within their stone work, which continue to amaze engineers and historians to this very day. IntoTheMap takes a technical engineering approach to this to see if it can be explained, and how their flatness is actually achieved with the resources available to them.

What is flatness? It is fundamentally about how close a surface is to a perfectly flat plane.To measure it, check for the highest divergence at a certain point. Most modern standards, including those from the American Society of Mechanical Engineers (ASME), describe flatness in three major categories: The rough surface is defined by the first class, and it can range from a flawless plane of up to 4mm to 1.25mm. If further enhancements are desired, machined surfaces can vary by 0.2mm to 0.05mm, or 8 to 2 thousandths of an inch. Precision surfaces can range from 0.025mm to a grain of salt.

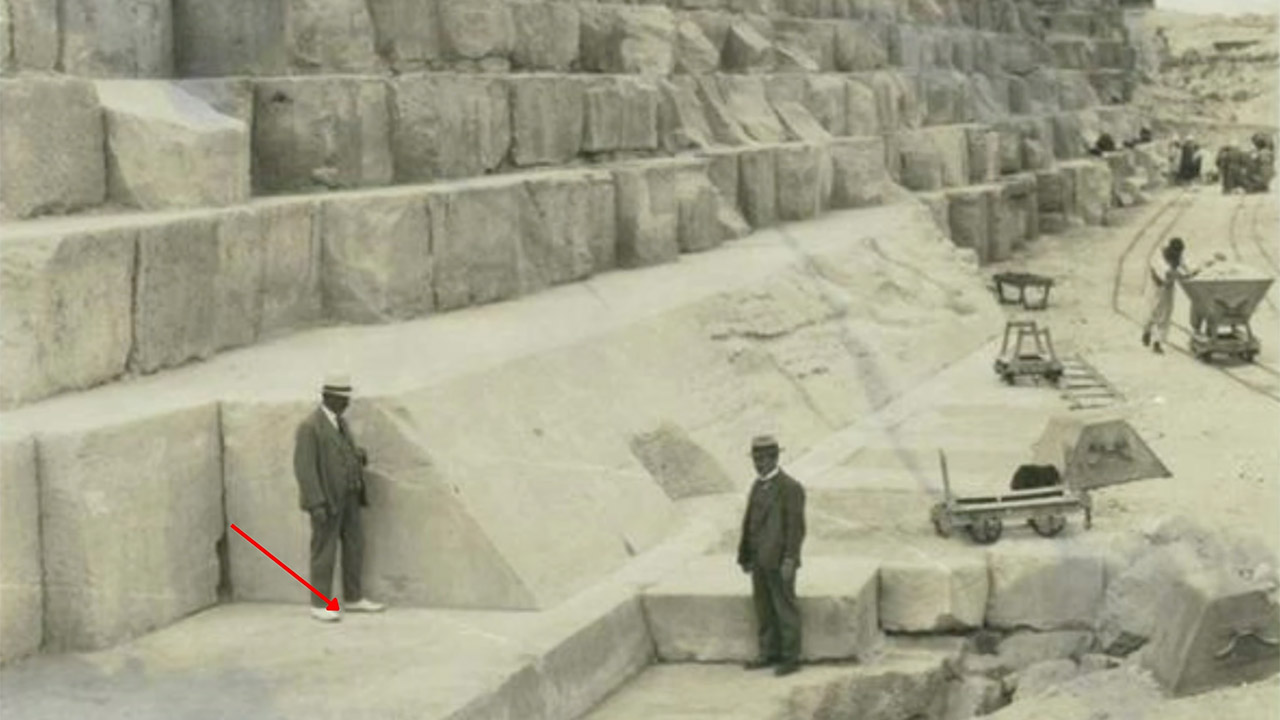

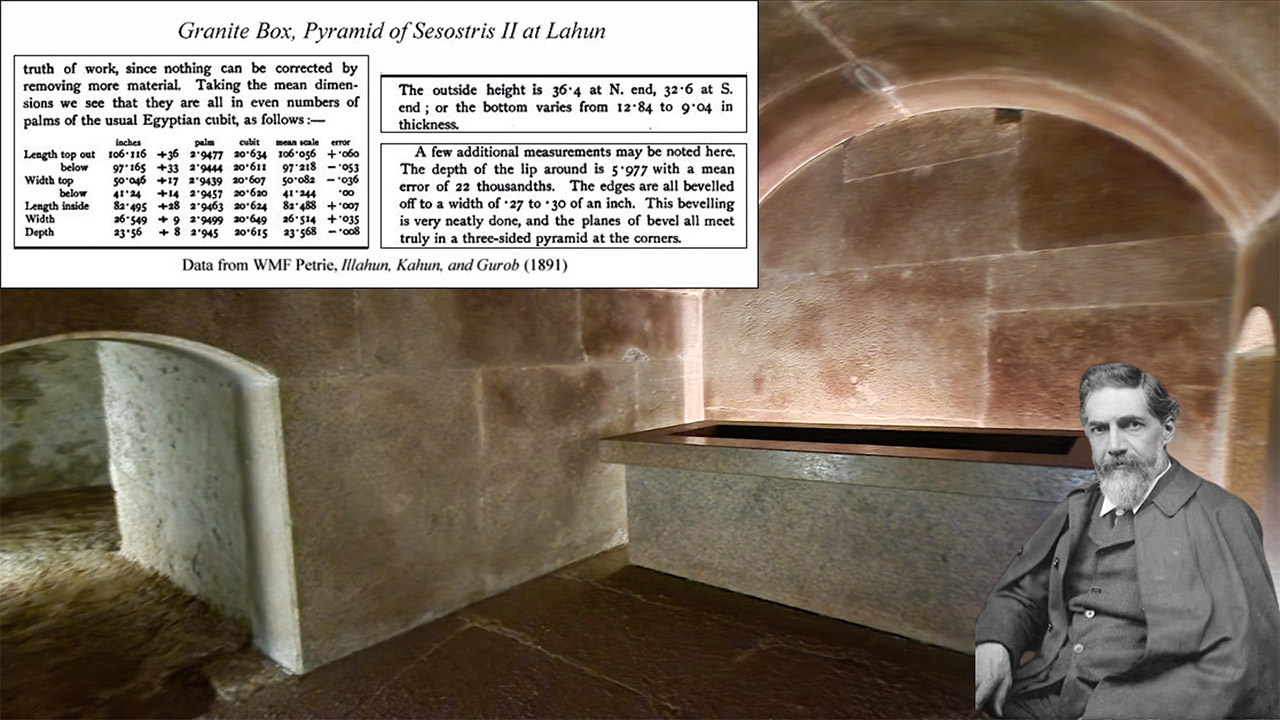

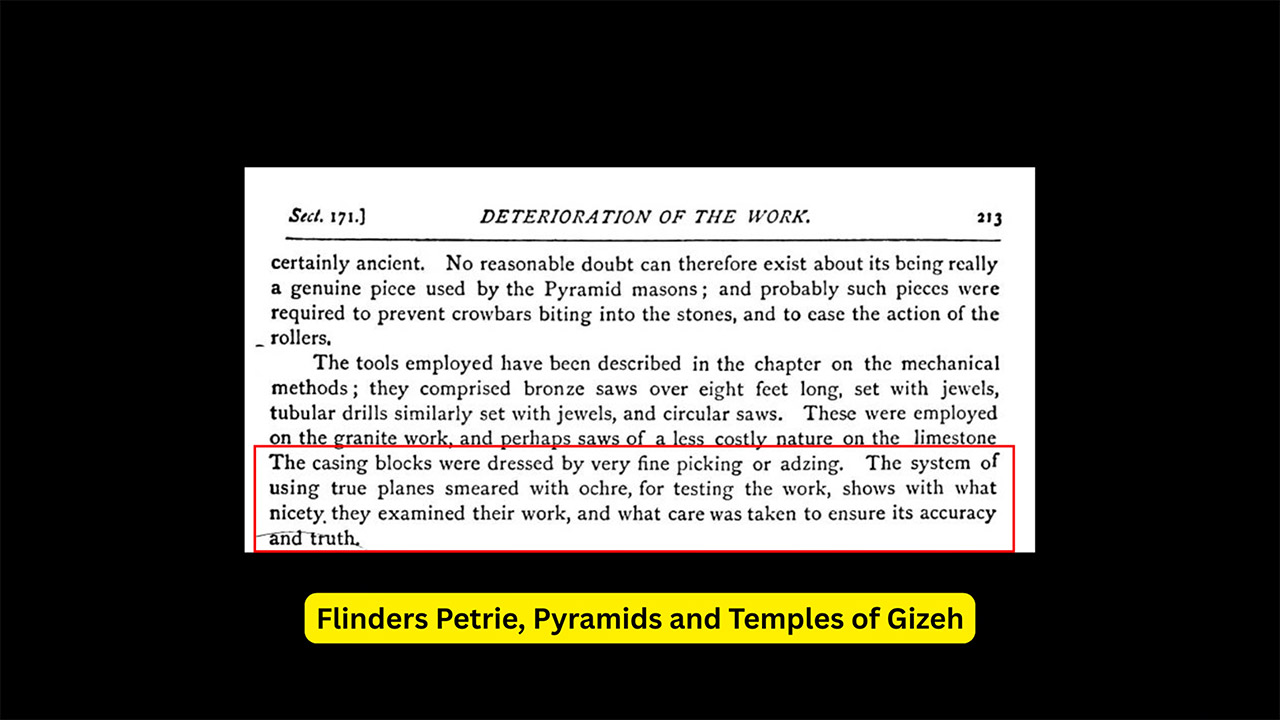

Historical measurements support the idea that Egyptian work falls solidly in the machined range. In the nineteenth century, a researcher named Flinders Petrie looked at the various aspects of the different eras of human history, including the inside of the pyramid of the Egyptian king named Khufu, and a sarcophagus within the pyramid of the Egyptian king named Senusret II, who built the Lahun Pyramid. He found out the edges were relatively straight and leveled, with a variation of a few in the thousands of an inch, signifying a slight curve or deviation from the other sections, but the actual measurement of the distance between the stones of the Great Pyramid was only 0.5 mm.

Nowadays, there are claims about how good the Egyptians were at achieving flatness, ‘at an aircraft level’ or even in microns, and it’s all about these granite boxes in the Serapeum, but the truth is that no one has actually measured those things with the necessary equipment, such as surface plates, dial indicators, and laser interferometers. Simply placing a straight edge or laser beam to test if they line up will reveal nothing about how flat they are over time.

However, the Egyptians were able to complete these tasks mostly because of their patience and precise preparation. One striking thing is Joseph Whitworth’s so-called ‘three-plate lapping method’, which was invented in the seventeenth century despite the fact that the basic concept existed much earlier. The idea is simple: take three plates, rub two of them together with abrasives, and color-code the high points before turning them over to ensure they match. After that, you add a third plate and rub until all three plates are in sync with the desired accuracy. The Egyptians likely simplified this process by designating the high points with red ochre and then using whatever abrasives and tools they had on hand, such as quartz sand or emery. To obtain a perfectly smooth surface, they’d just make a slurry of water and oil and be done.

This rubbing technique works very well with granite and other hard stones. Of course, it’s possible that the painters began with the raw materials available from the quarries, mixed a number of them together to get them close, and then refined each one individually from there. The degree of variation that exists with regard to the finished works, some of which are nearly flawless and some of which exhibit a number of imperfections, suggests that this was a skill learned across a number of generations rather than one that was mass-produced.

[Source]

Ancient Egypt’s Mastery of Flat Surfaces is a Masterclass in Precision Without the Mystery

#Ancient #Egypts #Mastery #Flat #Surfaces #Masterclass #Precision #Mystery