Building a 3D-Printed LEGO Castle That Fits a King

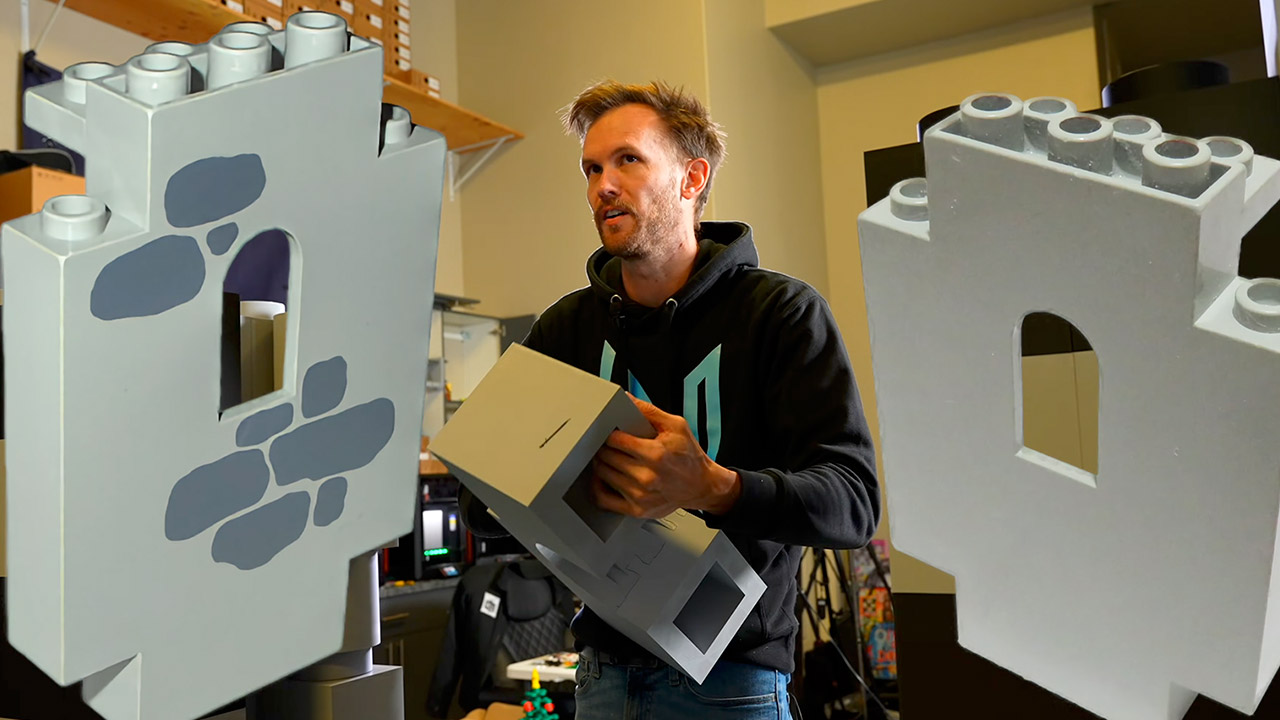

YouTuber ‘Nate from the Internet’ has great memories of a 1984 LEGO kit called King’s Castle, which was usually an afternoon’s worth of clashing knights and crumbling walls when he was a kid. Years later, he had a desire to return to that childhood toy, but his plan was to take it to a whole new level, such that playtime became a construction project in and of itself. To accomplish this, he used a 3D printer to reproduce the complete set at 20 times its original size, block by block and turret by turret.

Each of the 664 pieces in the original instructions needs to be reworked. Nate had to go over each one using computer software, scaling up the measurements in all three dimensions. The small bricks were easy to complete all at once, while larger elements such as walls and arches required many portions before being reassembled and re-glued. Fortunately, he had devised a brilliant solution: interlocking rails on those components, allowing them to snap together neatly before being locked into the rest of the entire. He also had to increase the size of the classic LEGO connections (studs and tubes) so that they could complete the job without requiring any adhesive. The colors remained very similar to the original set, with grays for stone and reds for banners, all printed layer by layer in special long-lasting PETG filaments.

Printing alone took months, a constant, nonstop activity with hundreds of Prusa machines chomping through spools of filament one after the other, cranking out new pieces overnight. Many of the large blocks were divided into four or five distinct pieces in order to fit everything together so tightly and then do the dovetail edges that make the seams nearly disappear when everything is reassembled. Unfortunately, this entailed a lot of hand pounding in the connections, which was a tiresome operation that took a toll on his arm and required him to wear a wrist brace.

When it came to assembly, it was a true test of patience; the early walls sailed up in no time, and the panels clicked into place like giant puzzle pieces. However, as you progressed higher up, ladders became more difficult. Not just any ladders, but custom ones that fit the set’s décor. Arches, on the other hand, proved to be the worst, especially the wonderful one over the gate. Nate ended up dividing it down into three sections: a foundation, a soaring curve, and a sort of mirror, each with extra studs for support. Fitting it all together needed precise precision; no room for error, no gaps, or the whole thing would come apart.

The main entrance was flanked by four smaller arches that were dovetailed into the wall panels, giving the impression that everything was one continuous piece. As the parts were put together, the building grew in size.

Nate went all out with the decorations as a last flourish, hanging banners from printed poles with fabric designs etched onto the plastic, giving the whole thing a sense of life. The turrets on the corners are sharp enough to silhouette against a window and add to the overall impression of grandeur. Inside, the chambers are divided by detachable floors, keeping with the LEGO principle of modularity. He also squeezed in a few side projects, like as a nearby printed Christmas tree made of green hubs and lighted by tucked-in LEDs.

[Source]

Building a 3D-Printed LEGO Castle That Fits a King

#Building #3DPrinted #LEGO #Castle #Fits #King