Building a Bicycle Wheel with Nautical Rope Spokes Has Surprising Results

A bicycle wheel with ropes instead of spokes seems like a prescription for catastrophe, but someone has managed to design one that rolls, retains tension, and can support the weight of a rider touring over rugged terrain. The end effect is stunning, halfway between the DIY inventiveness of a backyard shed and a genuinely innovative rethinking of how wheels work.

Adam from TartyBikes spent an eternity in his garage, fiddling on his prototype for hundreds of hours before finally assembling a working rope-spoke wheel. For inspiration, he went to commercial materials such as Berd spokes, which are ultra-high-molecular-weight polyethylene ropes used to manufacture wheels that are lighter and stronger than steel spokes. Of course, at a premium cost. So Adam decided to attempt creating his own version at home with whatever parts and bobs he could find easily.

RANHOT Electric Bike for Adults, 750W/1000W Peak Motor,28MPH, 48V 13Ah Lithium Battery, 25-45 Miles…

- Classic retro design, modern power: Experience the perfect blend of timeless style and modern technology. Our electric bikes feature a sleek 20-inch…

- Powerful performance for every ride: Equipped with a robust 48V 750W (1000W peak) brushless hub motor, this e-bike deliver speeds up to 28 MPH. The…

- All-terrain capability & superior comfort: Tackle any path with confidence! The 20″×4.0″ wide snow tires and front suspension fork absorb bumps and…

He chose the Robline DM20, a nautical rope manufactured of the same ultra-high-molecular-weight polyethylene as the commercial Berd spokes. The material floats, resists wear and tear, and basically stays place under a load. Here’s the kicker: each length of that rope can withstand around 450kg of pure tension before fraying rather than snapping. That is significant because every spoke in a wheel is constantly under tension; the rim is just suspended from the hub like a miniature suspension bridge.

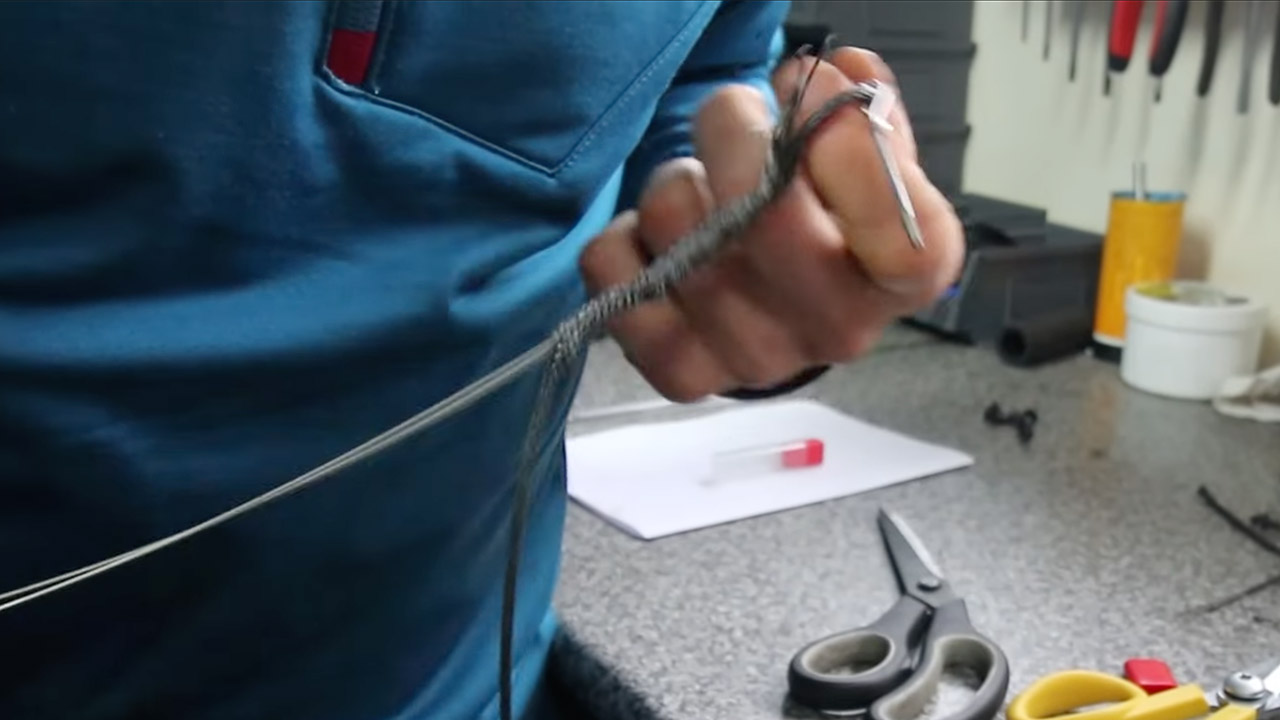

Steel spokes, of course, must be precisely cut to length, threaded through the hub and rim, and tensioned with the small metal nipples. In contrast, rope requires a whole different strategy. Adam devised a solution by making little loops on the hub end with ordinary stainless-steel Sapim Race spokes. He bent the spoke into a clean 180-degree loop on a special jig, twisted one end to the other for grip, ground down the twist flush, and welded the union with silver solder, applying flux and heating it up nice and hot to produce that cherry-red glow. After applying the solder, he immersed the loops in a caustic soda solution to remove any corrosive residue.

On the rim side, he applied a splicing method he had learned while sailing. He shortened the end of the rope by slicing away the strands over around 100mm until just one strand remained, then tucked that tapered section back into the rope’s hollow center. And that part acts like a Chinese finger trap: pull on the rope, and the outside braid tightens straight up around the concealed core, forming a joint that holds practically the entire strength of the rope without any knots. The spliced end is then guided through a normal spoke nipple on the rim. Double-square nipples provided him more wiggle room to fine-tune the tension, compensating for the rope’s modest stretch when under strain.

Lacing follows a typical three-cross design, and a single piece of rope is securely weaved between the hub flanges, with a hitch that holds everything in place as you increase the strain, thereby transforming one rope into two opposing spokes. That makes things neat, with fewer splices to deal with, while still keeping the entire wheel properly balanced. The process of getting everything set up in the correct tension occurs in stages. Because rope stretches far more than steel when subjected to the same force, Adam designed the wheels to be a few millimeters short and allowed the material to settle in during the initial pulls. When it came to getting it just right, he merely relied on feel and evenness of pluck; steel and metal respond differently when it comes to damping vibrations, so perfect numbers aren’t enough.

The final front wheel, which consists of a 24-inch downhill rim, an Industry Nine hub, and a Lightbicycle carbon rim, weighs approximately 700 grams. If he had used steel spokes and nipples for the identical build, we’d be looking at an additional 80 grams. On the bike, the high-frequency buzz from rough surfaces has been replaced by a quiet, compliant ride that simply filters out any chatter and may even assist lessen arm pump on long descents.

[Source]

Building a Bicycle Wheel with Nautical Rope Spokes Has Surprising Results

#Building #Bicycle #Wheel #Nautical #Rope #Spokes #Surprising #Results