Rare OPPO Factory Tour Offers Sneak Peek at Smartphone Precision

Scotty Allen of Strange Parts traveled through the gates of OPPO’s huge factory outside Shenzhen, China, where flagship phones like the Find X9 Pro are produced. For someone who had spent years building electronics from market booths in Huaqiangbei, this felt like the end of a long process.

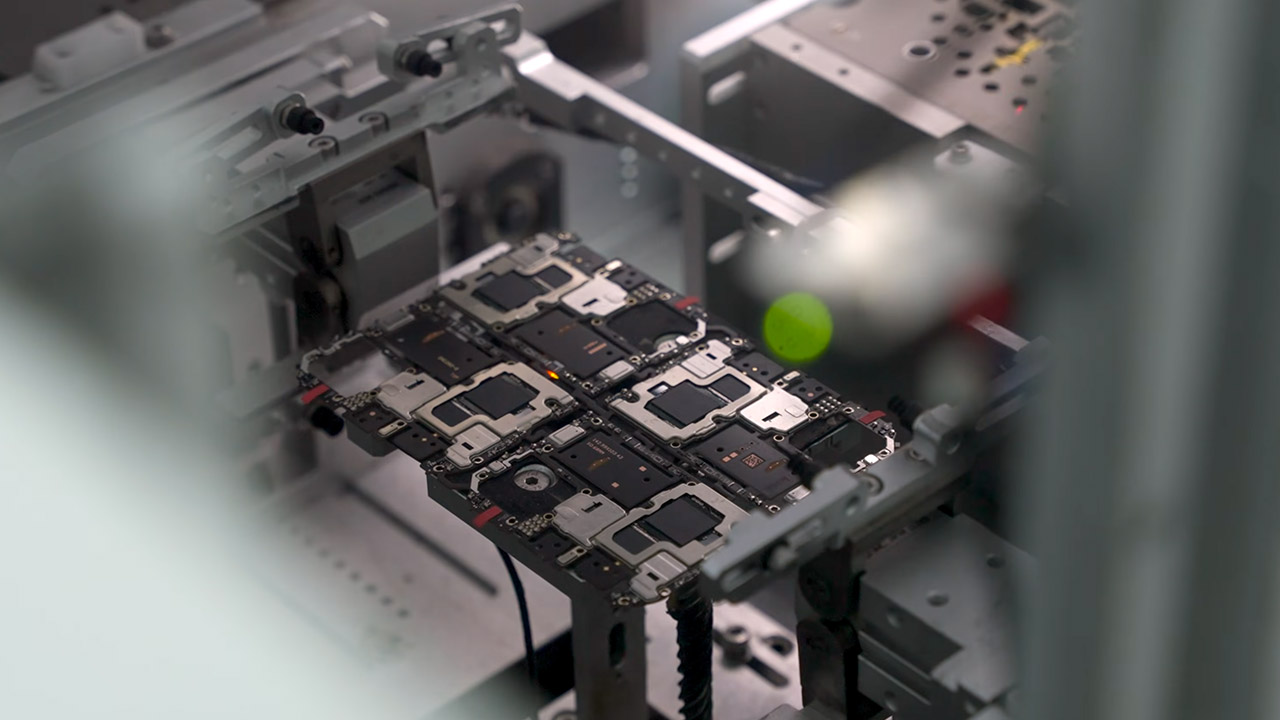

Mr. Shan, the head of manufacturing, greeted him with a firm handshake, their remarks relayed via radio translators fastened to their ears. Screens nearby flickered with data streams that will soon go out for the tour. They started with the logic board, the phone’s brain, which has a CPU, circuits, and ports for cameras and displays. The three-layer stack, a brilliant engineering fold that squeezes more pieces into less space, immediately drew my attention. Each tier included surfaces for components, transforming a flat puzzle into a compact tower. A riser connector between them produced just enough of a space, which was soldered tightly to hold the whole device together.

SAMSUNG Galaxy S25 Ultra, 512GB Smartphone, Unlocked Android, AI Night Mode Camera, Snapdragon 8 Elite…

- MULTIPLE TASKS WITH ONE ASK: Streamline your day with an assistant that gets you. Ask it to Google search for a pet-friendly vegan restaurant nearby…

- START THE DAY SMARTER: Stay one step ahead with a phone that gives you the info you need before you even know you need it with Now Brief.²

- REDUCE THE NOISE. REVEAL THE MAGIC: AI Camera with Audio Eraser lets you capture vibrant videos in low light and minimize unwanted noises so you can…

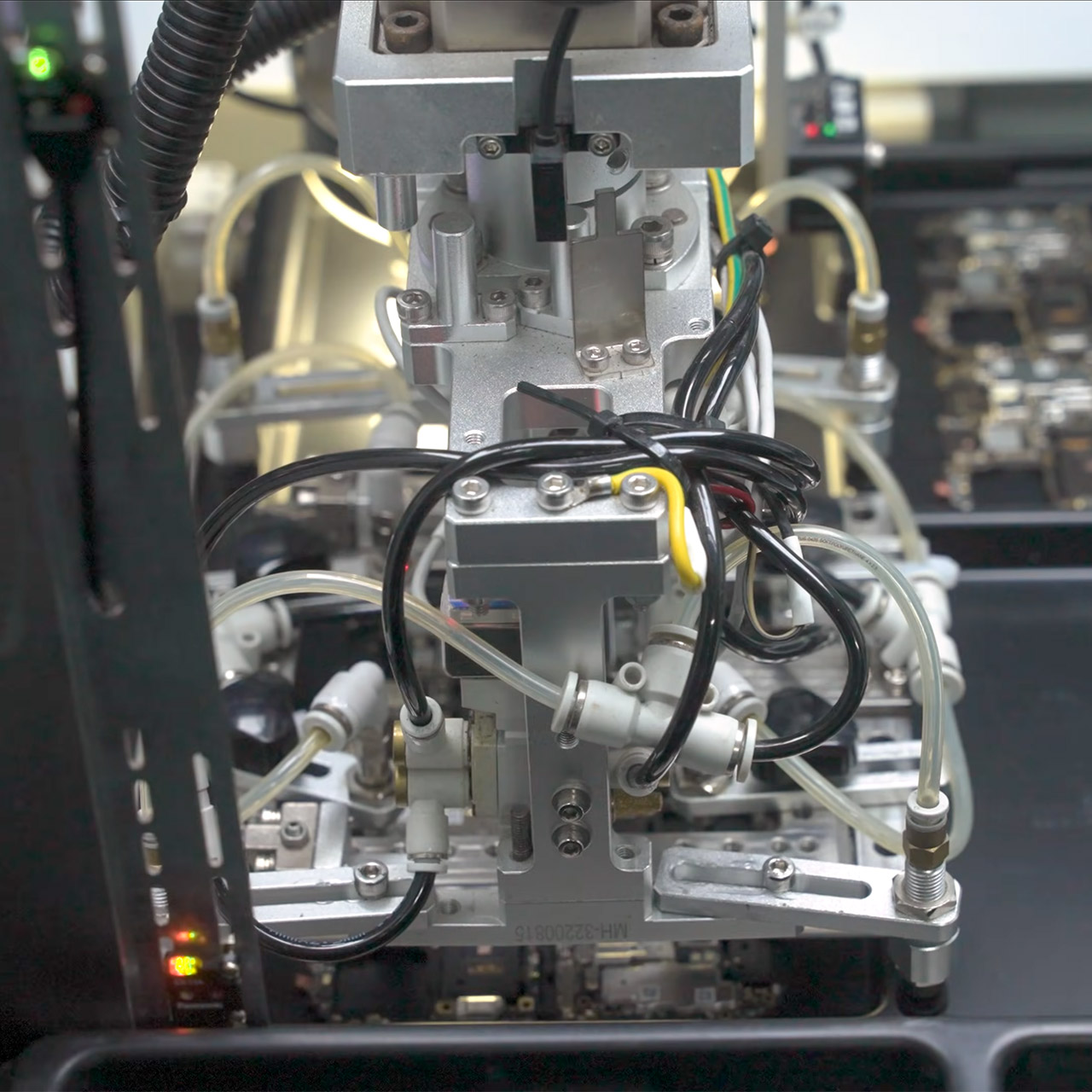

Disassembling a prototype board revealed the features up close: thermal paste squeezed into secret recesses to wick heat away from the chips beneath. Mr. Shan explained that every decision was made with battery life in mind, including the ability to add larger cells without bulking out the design. Engineers hovered nearby, ready to step into the surface mount technology line, or SMT, where these boards were being assembled from bare panels.

Panels of four PCBs arrived on firm trays to keep them flat and were fed into a line that never slept, producing 400 boards each hour, 24 hours a day. Robots whisked them along, flipping for work on both sides with little break. Solder paste was applied initially, using a screen-printing machine to put it in precise dots that were then tested for even coverage using lasers. Then came the placement machines, heads plunging into trays of tiny resistors and capacitors and dropping them with sub-millimeter precision.

Reflow ovens were able to heat the boards just enough to melt that delicate paste into solid linkages, while also providing a blast of nitrogen to clean them and prevent oxidation. Then came the testing phase: probes were attached to ensure that there were no shorts, and software was loaded to fine-tune radios for a decent signal on cellular, WiFi, and Bluetooth. You’d have around 5 workers per line keeping an eye on things, placing new parts on reels and removing jams, but their hands would seldom even touch the boards. Any suspect panels were routed to a reject buffer, while the excellent ones continued to produce at a healthy 99.8 percent output.

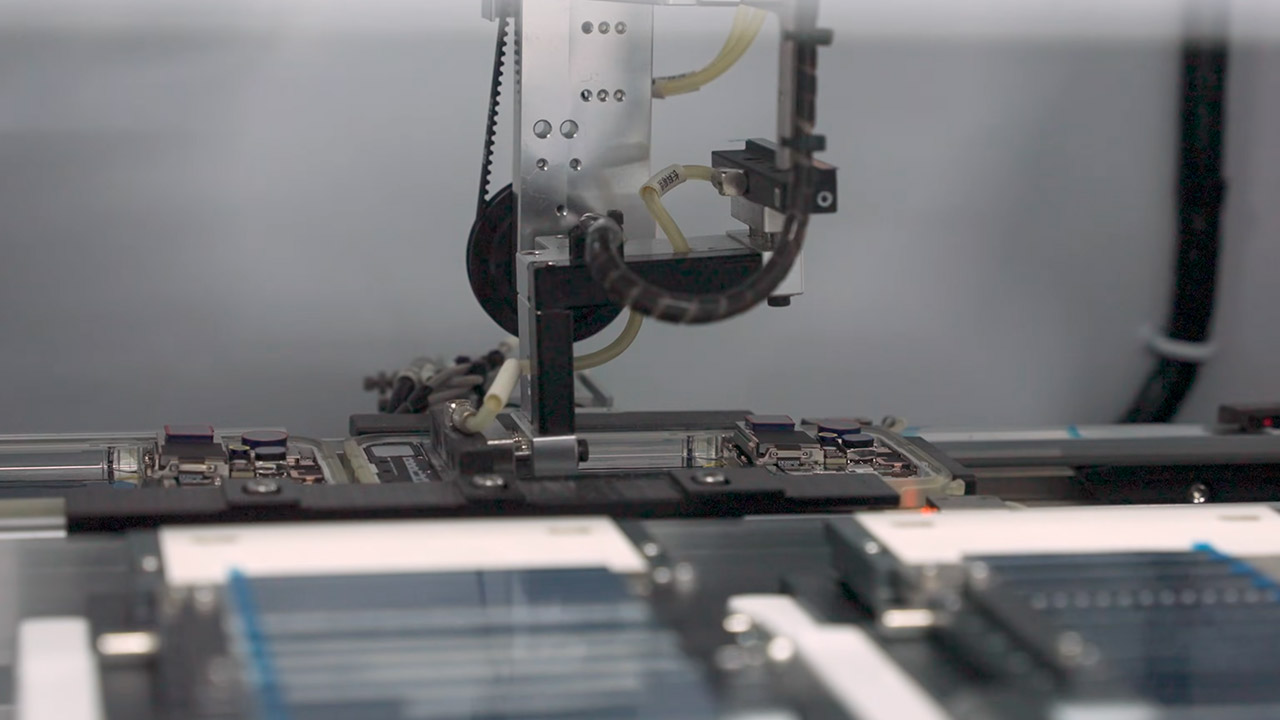

The boards then proceeded to final assembly, where all of the screens and metal frames waited in line. Workers in clean rooms with purified air went carefully through the intricate joints. Screens arrived first, and each was scanned for a barcode, followed by cracks or dust spots. These panels were not your typical screens; they had flexible circuits that bent sharply to allow for tiny bezels, all protected by a layer of plastic that was inserted under a vacuum, directly over the susceptible edge.

After applying a few spots of glue to the frame’s curve, the surfaces were cleaned off with plasma and nitrogen to prime the adhesive for a water-tight seal. Then, in a dedicated booth, one man removed the stickers off the camera cutouts, while a blower blew away all the static to keep particles at bay. The screen was fitted into the frame at a precise angle, guided by the 3D lasers, and then clamped in for a three-hour cure. To ensure that the seal was intact, they simply pumped air into it to see if it could withstand all of the high-pressure water and burning that could come its way.

Next came the batteries, which were neatly packed in foam shields to protect them from drops. A hand was used to carefully insert them, machines pressed them into place, and screws were used to tighten the circuit board. Cameras were then installed in casings with small periscope lenses that reflected light to far-away sensors to achieve the zoom effect without adding weight. The back cover was simply snapped on, followed by around an hour in a curing oven to set the bonds.

The testing stations followed next, all lined up in a row like an obstacle course, with each phone going through a series of tests. Burn-in cabinets were put through their paces during an 8-hour period, with screens flickering and batteries being tested to find any weak points. Shakers then roughed them up, as if they’d fallen off a table, and cameras were thoroughly cleaned under harsh lights. Probes simulated button presses and even the camera’s snap key, measuring the response to varied forces.

Rare OPPO Factory Tour Offers Sneak Peek at Smartphone Precision

#Rare #OPPO #Factory #Tour #Offers #Sneak #Peek #Smartphone #Precision