What it Takes to Craft the Perfect ATV Battery You Actually Need

People usually go for store-bought batteries because they are less expensive and easier to use, but when performance is critical, custom work is the way to go. A worn-out lead-acid battery in a midsize electric ATV prompted one builder to replace the factory pack and start over using LiFePO4 cells. The chemistry has some obvious advantages: it has a better energy density than traditional lead-acid batteries, provides consistent power delivery even when the pack is low on charge, and is far safer than many other lithium varieties.

Well Done Tips selected 16 EVE C40 cylindrical cells, each with a 20Ah capacity, 60A continuous discharge rating, and 100A peak rating. They placed them in a 16S1P configuration (16 cells in series and one parallel string) to get a nominal 51.2 volts. When completely charged, the pack reaches around 54.4 volts before settling to around 54 volts after some rest. That voltage behaviour turned out to be quite crucial. The inventor had planned a 15-cell system, but everything fell apart (literally) after the cells started working, so they changed the design, added an extra cell, reprinted the holders, and then had to reassemble the entire thing.

Sale

Jackery Portable Power Station Explorer 300, 293Wh Backup Lithium Battery, Solar Generator for Outdoors…

- SPEED UP YOUR RECHARGEABILITY: It takes only 2 hours to recharge 80% battery of the power station through the wall outlet and 60W PD USB-C port…

- SAFE & STEADY POWER SUPPLY: Armed with a 293Wh lithium-ion battery pack, the Explorer 300 features 2 Pure Sine Wave AC outlets that deliver stable and…

- POWER YOUR EXPECTATIONS: Featuring 2* AC outlet, 1* PD 60W USB-C port (input/output supported) , 1* fast charge 3.0 port, 1*USB-A port and 1* DC car…

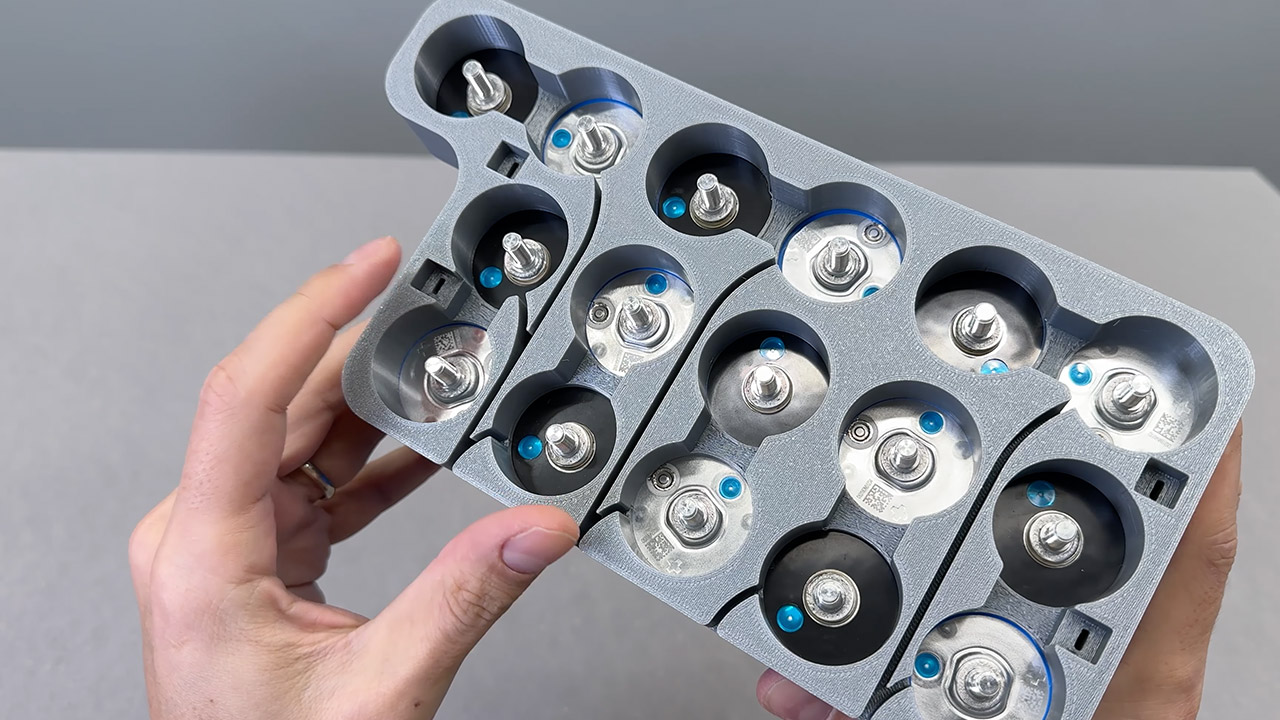

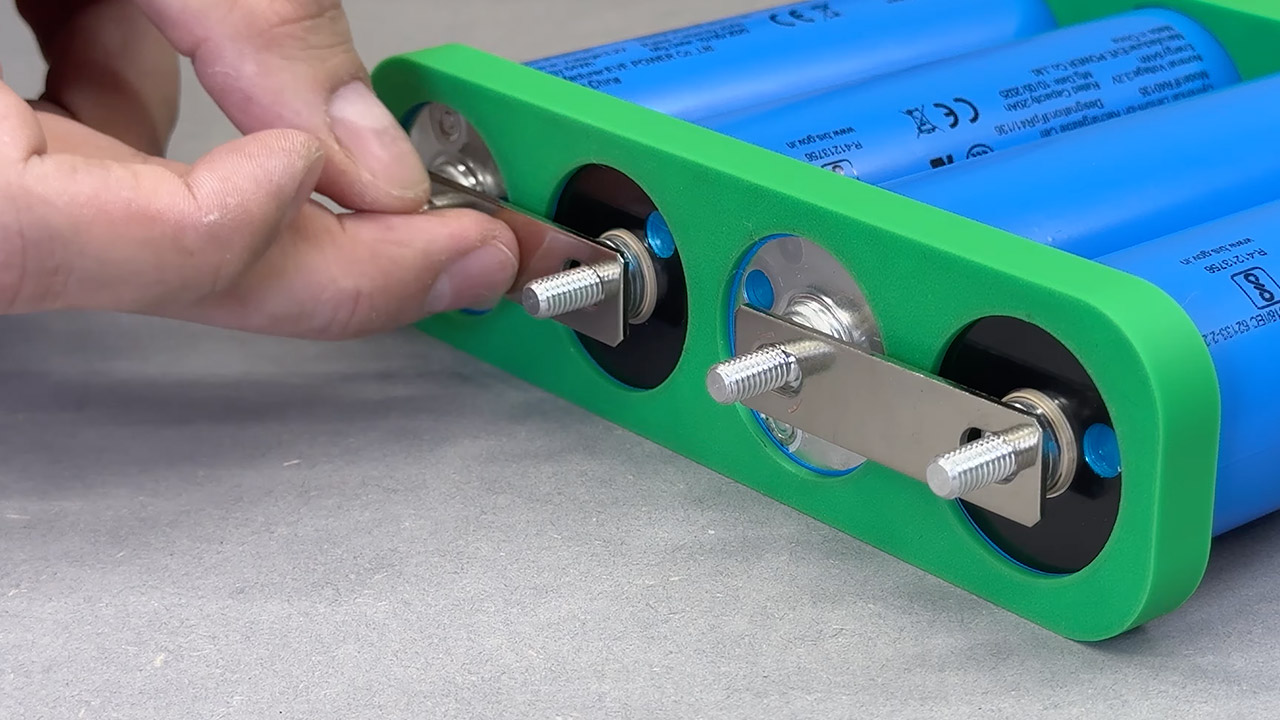

Building the framework began with the holders, which were custom designed and printed in PETG to fit the bigger cylindrical cells (40135 form factor). Channels routed those balance cables neatly, and some solid mounting points kept everything in place. Three perimeters and 15% infill made the parts sturdy without using more material than necessary. To keep the cells in place, they utilized four zip ties per holder rather than metal fasteners, which may loosen the terminals.

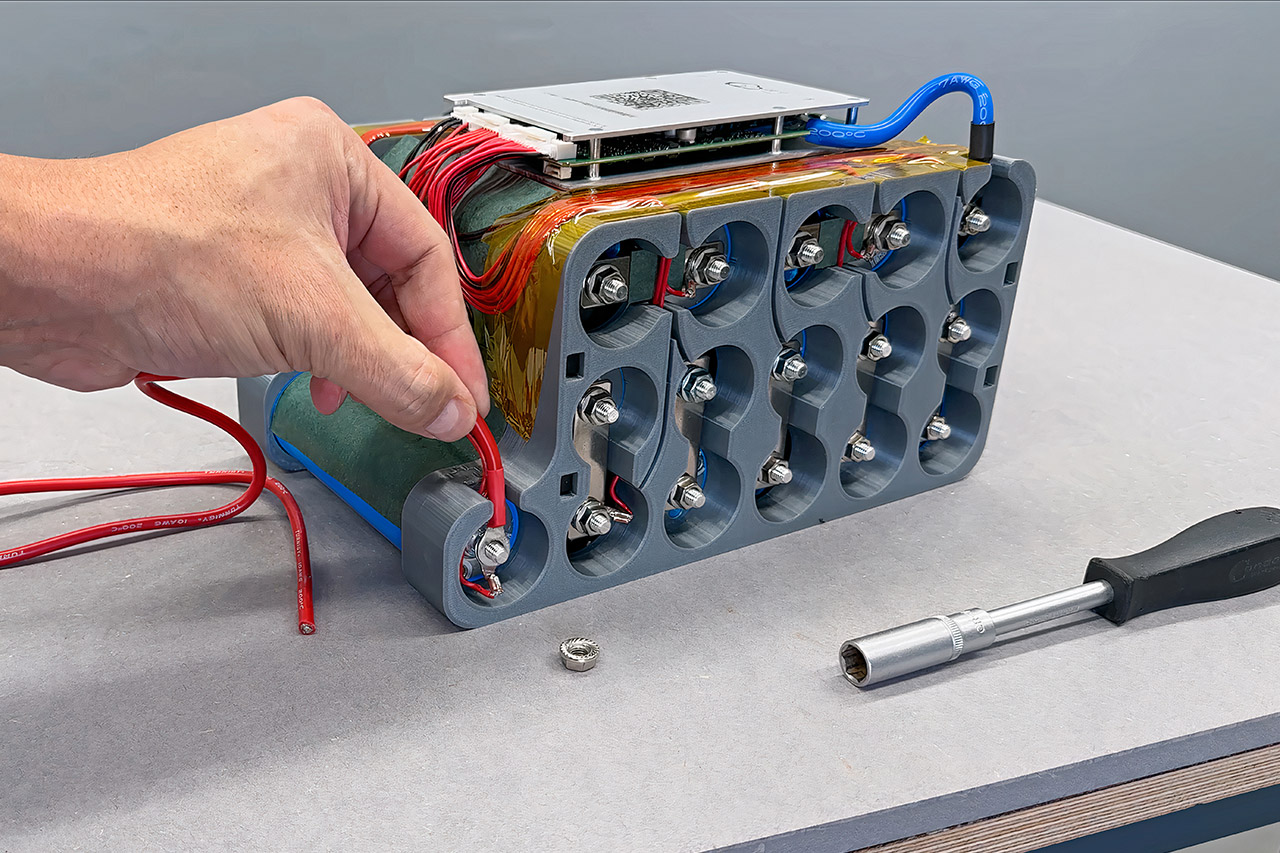

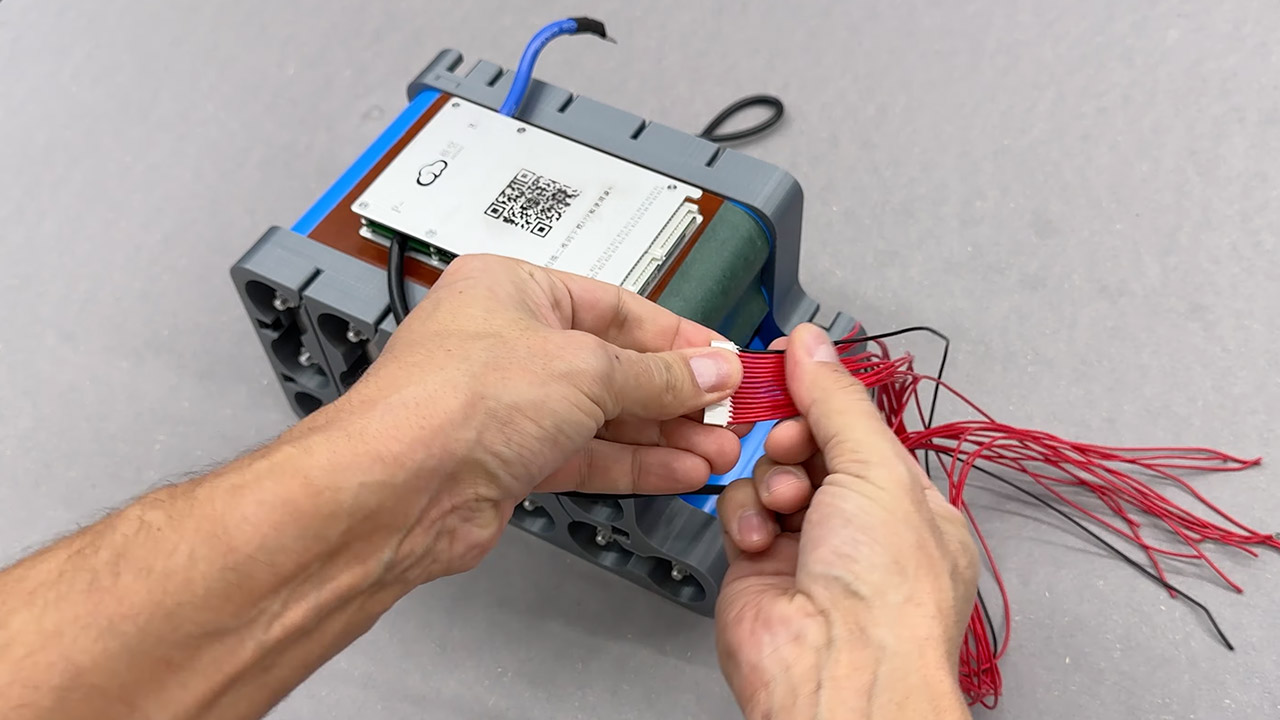

The cells were connected via nickel-plated bus bars. Each cell featured a screw terminal that accepted M6 nuts for a secure, tool-free assembly; no spot welding was required, which kept things simple. The balancing wires were brought in from the BMS and joined to the same terminals using crimped ring connectors. To manage the pack, a JK BMS type BD6A20S8P was chosen, which is rated for 80A continuous and 150A peak discharge and includes temperature sensors at both ends. The builder placed the BMS on a piece of fiberglass for insulation, then secured it with double-sided tape and cleaned up the cables. Everything was set up using the JK mobile app: simply select LiFePO4 chemistry, input the 16S layout, and set the cell capacity to 20Ah.

The main power leads were extended with 10 AWG silicon wire, and the output was terminated with XT90 connectors. A 3D-printed lid was used to cover the exposed connectors, and additional printed elements routed the cables while automotive sealant kept everything weathertight.

The final pack fit perfectly into the ATV’s regular battery box without requiring any alterations. A piece of plywood and some foam were used to keep it from rattling about or shifting, and the entire system weighed almost four times less than the original lead-acid pack, but having the same 20Ah capacity. Crucially, the power production remained steady from full charge to roughly 20% remaining, unlike lead-acid batteries, which faded away gradually. Charging was also much faster than the old lead-acid cycle, which required 8 hours.

Off-the-shelf batteries are fine, but they rarely meet your specific demands. Building this pack demonstrated how much better a tailored solution can perform in terms of weight, runtime, and responsiveness. The modular architecture also makes future modifications simple, and the entire cost was roughly equivalent to a replacement lead-acid battery.

[Source}

What it Takes to Craft the Perfect ATV Battery You Actually Need

#Takes #Craft #Perfect #ATV #Battery