ABB IRB6400 Robot Arm Gets Turned Into a Functional 3D Printer

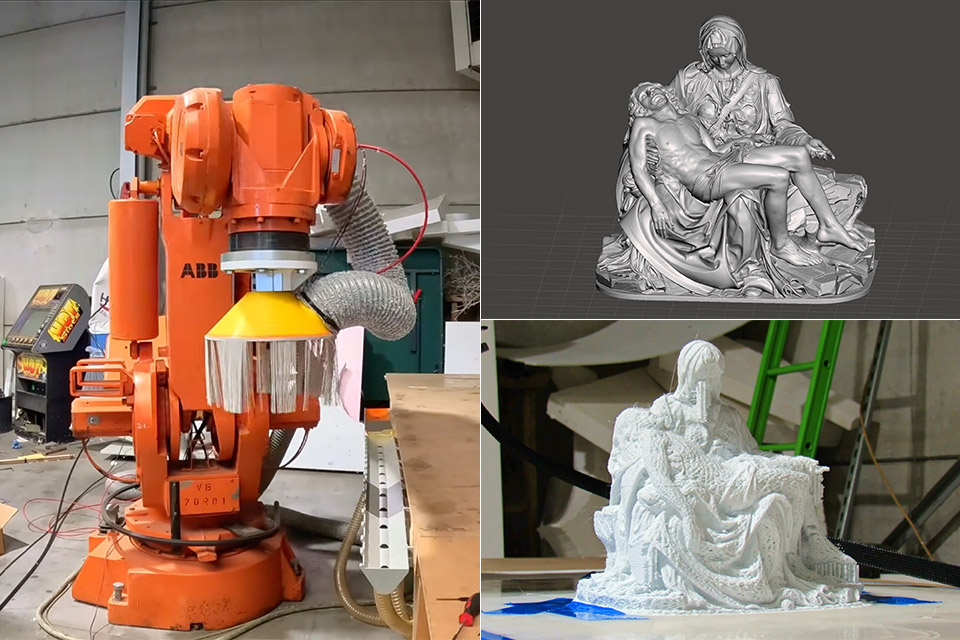

A huge industrial arm now slaps down layers of plastic rather than welding steel, a long cry from its factory floor roots. Brian Brocken got his hands on an ABB IRB6400, a 26-year-old two-ton workhorse that is often used to move huge payloads for large industrial organizations, and converted it into a fully functional 3D printer. The end result is a beast that combines the brute power of an industrial robot with the precision of a high-end printer, making items that dwarf any desktop 3D printer.

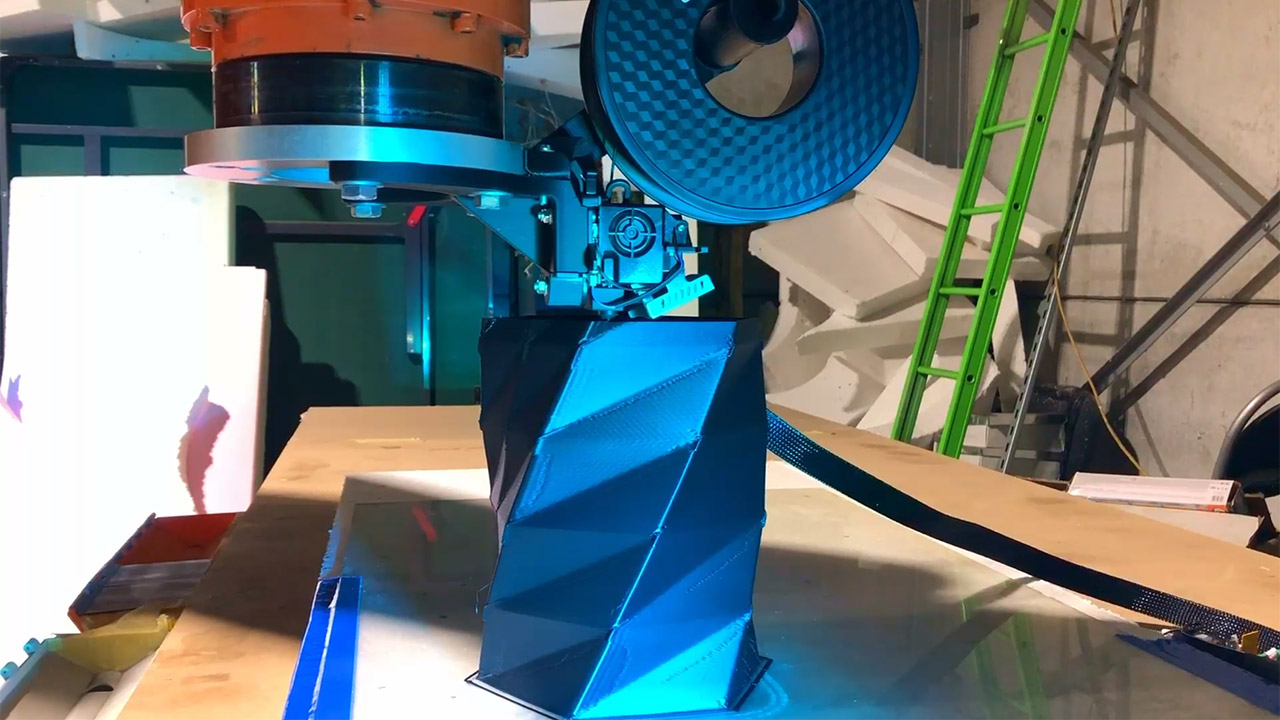

Industrial robots of this type are designed to transport huge heavy loads with ease, and the IRB6400 is no exception, capable of handling payloads weighing anywhere from 100 kilograms to 200 kilograms depending on how you configure it. Add a lightweight extruder to the mix, which barely registered as a burden on this gigantic machine, and you’ve created a 3D printer. Brocken connected a Creality Sprite Pro direct-drive extruder to a custom frame and spool holder that he 3D-printed in PLA with some very strong settings: five solid outer layers, a 0.4-millimeter nozzle, and 20% infill. Even during regular operation, the bracket easily supported the extruder and a full kilogram spool of filament.

Sale

Bambu Lab A1 Mini 3D Printer, Support Multi-Color 3D Printing, Set Up in 20 Mins, High Speed & Precision,…

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000…

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make…

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 Mini 3D printer takes care of all the calibration processes automatically,…

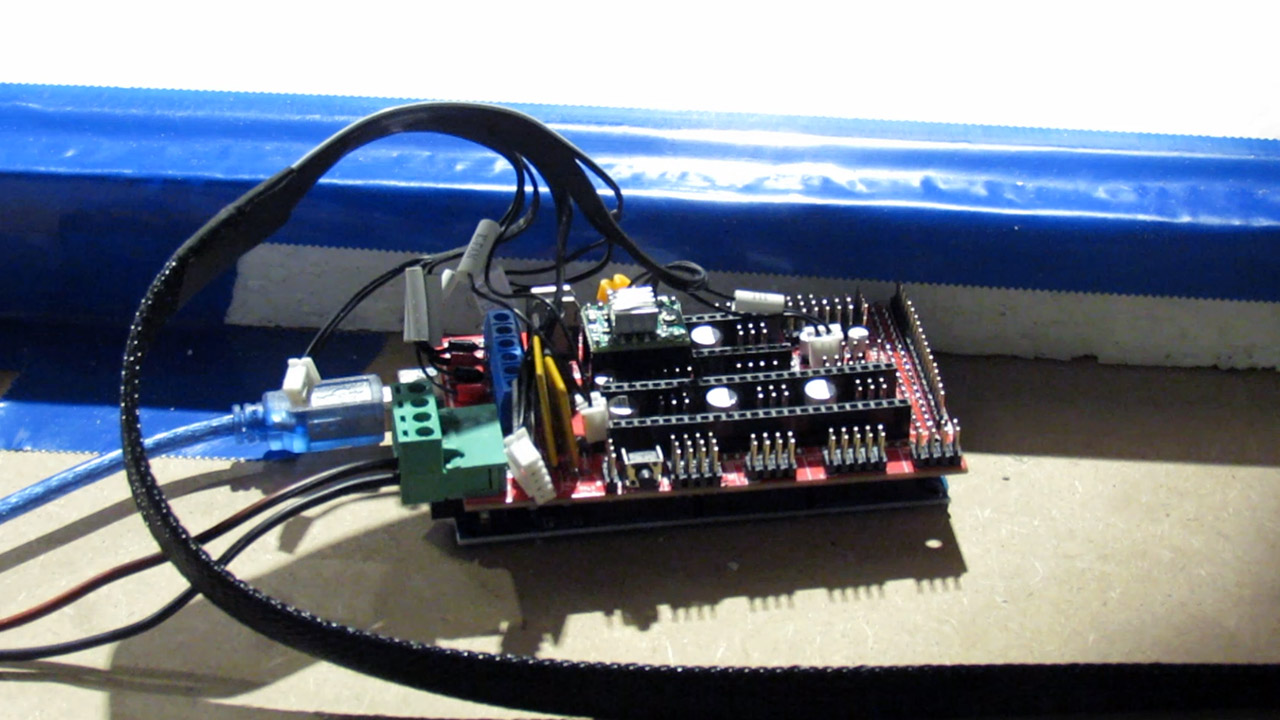

Getting the thing to work and print properly, however, was a very different matter. The reason for this is that the robot runs on ABB’s RAPID language via an ancient S4C controller that does not speak standard G-code, which is utilized by the majority of 3D printers. Plus, its memory is laughably little, owing to the fact that it is an outdated machine from the floppy disk era, thus it simply cannot handle large programs. Brocken created his own custom software that slices models with standard tools such as Repetier Host or PrusaSlicer, then converts the G-code to RAPID and streams it to the robot line by line. However, that wasn’t the end of the story; he also had to build a separate controller board for the extruder, an Arduino Mega on a RAMPS 1.4 board, just to get it to handle temperature, fans, and the stepper motor.

If the data was buffered, it would simply begin to drift out of sync. If you didn’t buffer the data and instead started sending it to the robot, it would hesitate between points on some intricate paths, resulting in that dreadful stop-start motion. It’s worth noting that getting the proper acceleration profiles for the arm and extruder was quite beneficial. Still, when it came to intricate shapes, the robot couldn’t seem to get it together; surfaces would appear rough due to the abrupt stops. Plain shapes, such as vases, produced more smoother results.

Brocken used a Revopoint Metro Y scanner to scan a replica of Michelangelo’s Pietà, which had been reduced to scale. The robot worked layer by layer, extruding PLA as it moved along the object’s 3D routes. While the results are interesting, the detail isn’t quite as good as what a genuine 3D printer can produce, but it’s a start.

[Source]

ABB IRB6400 Robot Arm Gets Turned Into a Functional 3D Printer

#ABB #IRB6400 #Robot #Arm #Turned #Functional #Printer