Boeing 777 Cabin Pressure Control System Teardown Reveals the Hidden Guardian of Your Flight

Every year, millions of passengers board a Boeing 777 and settle into their seats as the plane gently climbs to cruising altitude. Even the most experienced flyers are unlikely to consider the tiny little box of electronics and sensors that work tirelessly to make the air inside the plane safe to breathe.

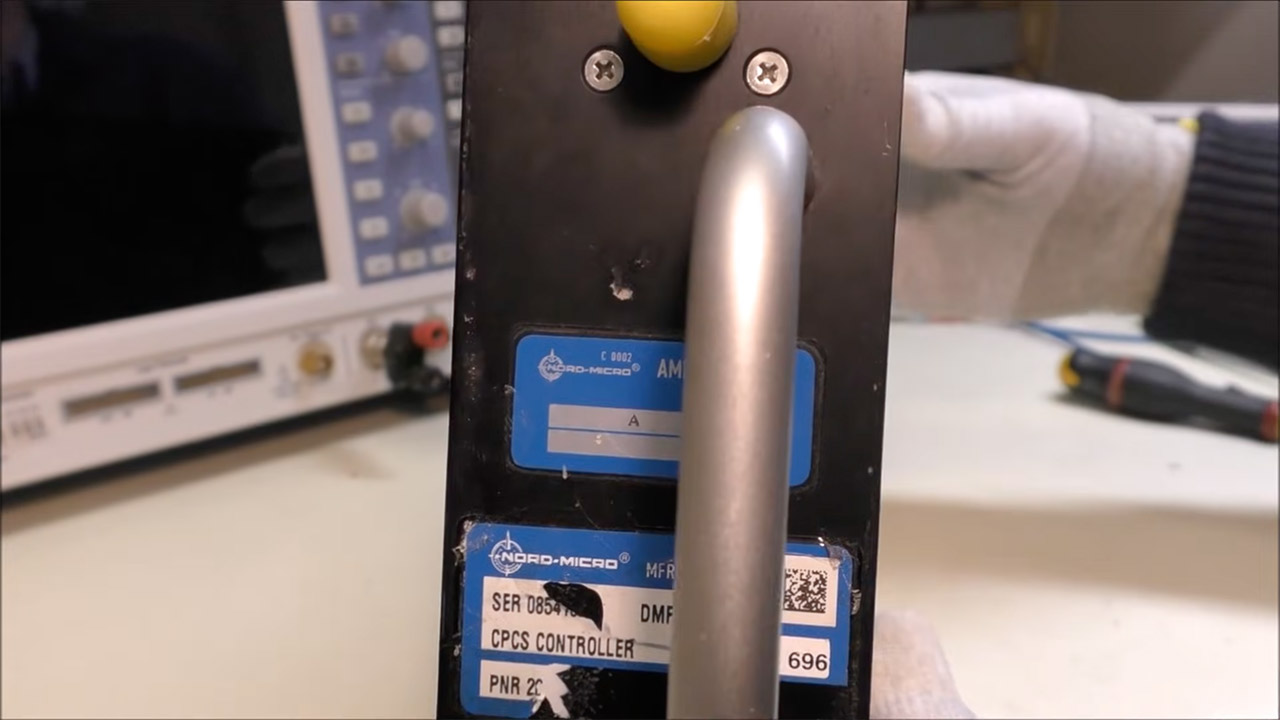

This equipment, known as the Cabin Pressure Control System controller, is the workhorse that maintains the proper pressure inside the airplane fuselage. We get an excellent peek inside one of these machines courtesy to a teardown by an aviation enthusiast named Michel, who demonstrates how the entire system works.

LEGO Icons Shuttle Carrier Aircraft Building Set for Adults – Spaceship & Airplane Model Kit for Adults,…

- 2 AVIATION LEGENDS, 1 BUILD – Recreate the iconic Boeing 747 and NASA Space Shuttle Enterprise with the LEGO Icons Shuttle Carrier Aircraft (10360)…

- DEPLOY LANDING GEAR – Turn the dial to extend the massive 18-wheel landing system on your airplane model, just like real flight operations

- AUTHENTIC FEATURES & DETAILS – Remove the tail cone, engines, and landing gear from the NASA shuttle and stow them in the cargo bay during flight

Air enters the cabin through engine bleed systems as hot, pressurized air. It is then cooled and conditioned by air packs before being supplied overhead to passengers. However, in order to maintain a constant air pressure within the plane, some of the air must be released, which is where the enormous outflow valves come in, one in the front and one in the back. The majority of the air will depart through the back valve, which is more effective in maintaining air circulation.

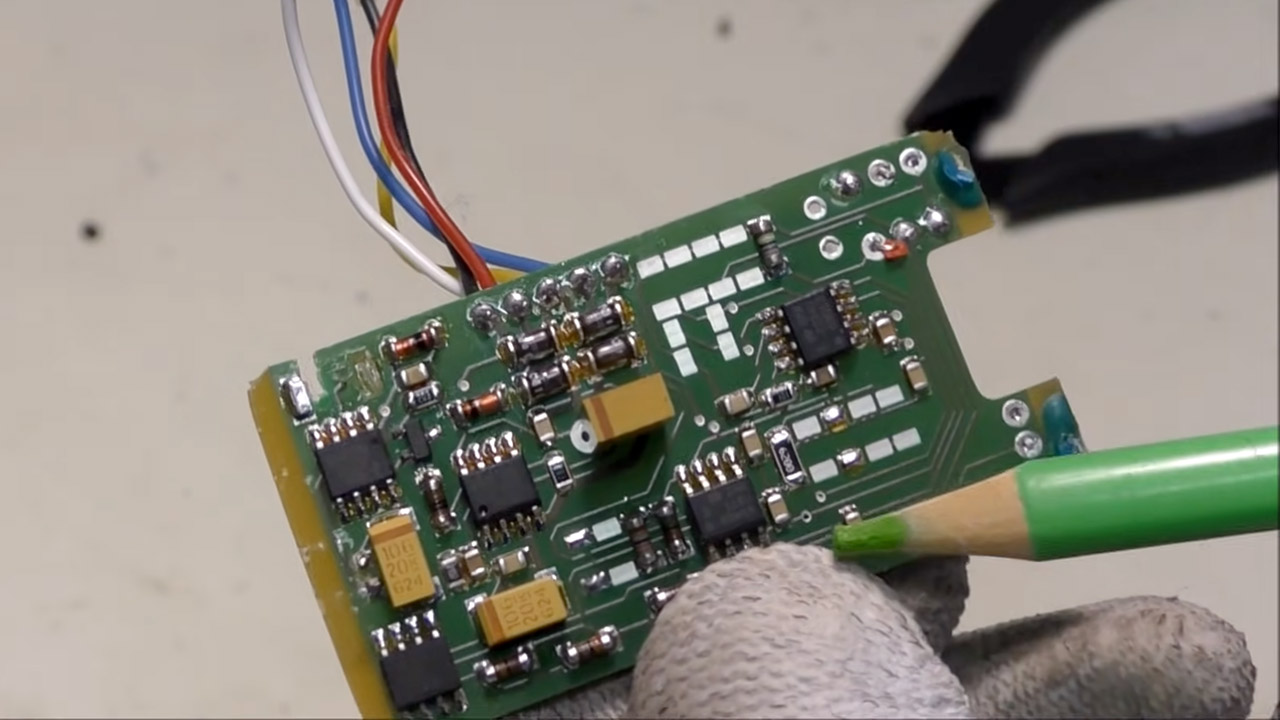

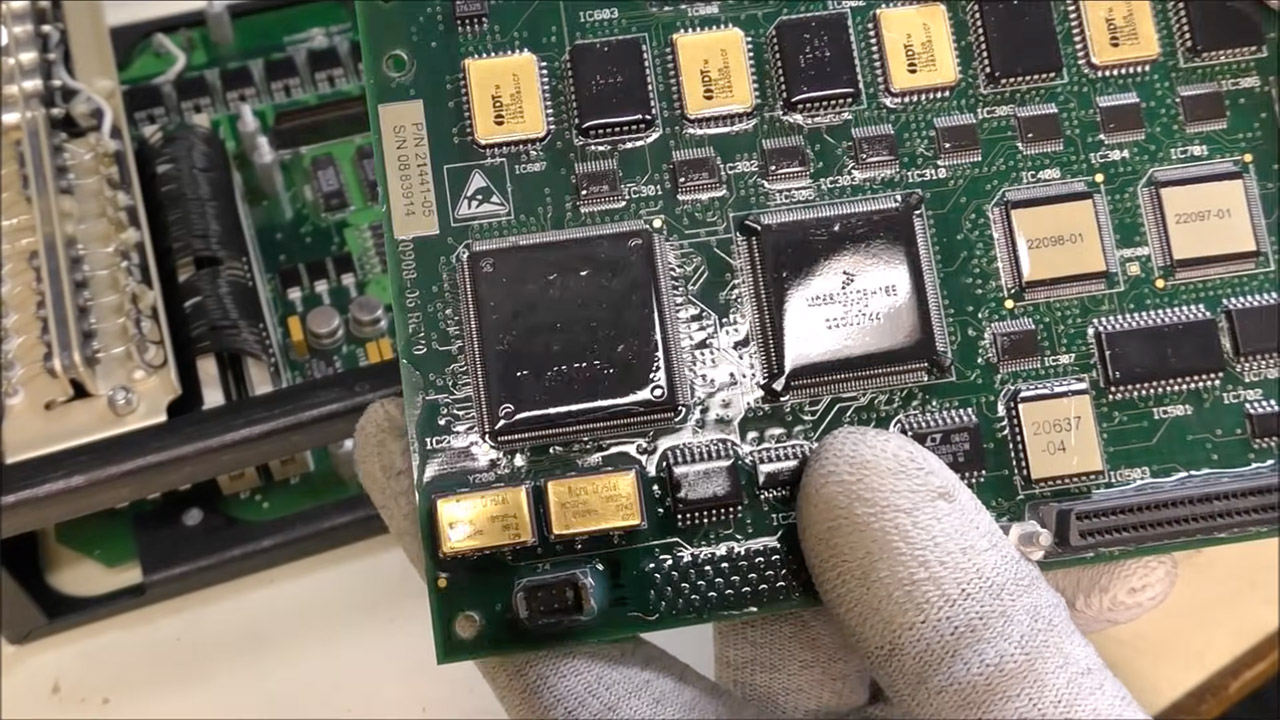

The controller operates the valves, making microscopic adjustments to maintain the ideal air pressure. Every 777 includes two backup systems, one of which is the controller. That’s because if one system fails, the other will take over, keeping the air safe to breathe at high altitude. When you open the sturdy metal container and peek inside, you’ll notice how dense the circuit boards are, and how they’re all protected from moisture and vibration by a unique coating. Furthermore, all of the connectors are secured to prevent them from vibrating loose.

At the heart of it all are two small pressure transducers manufactured by Nord-Micro. These are the devices that detect cabin air pressure utilizing a sophisticated technology known as piezoresistive. It operates by using microscopic silicon elements that vary their resistance to electricity as the pressure on them varies.

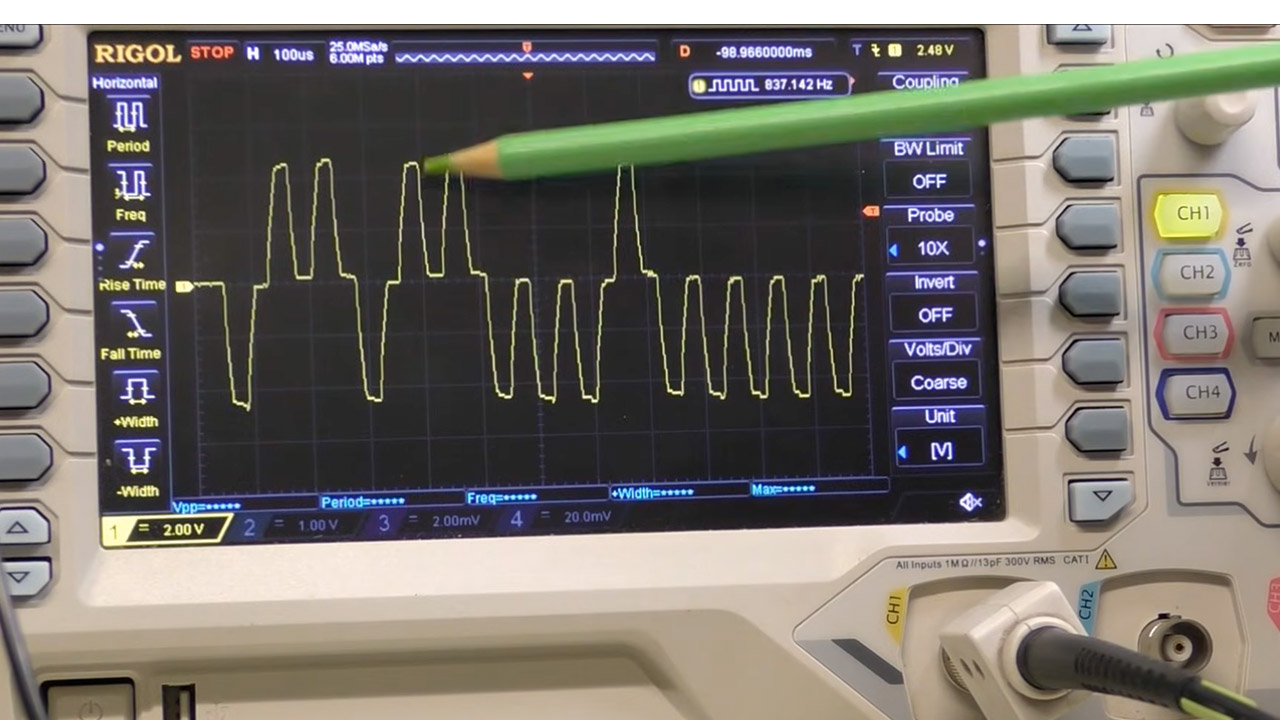

One of these transducers performs the primary function, while the other serves as a backup. What occurs is that both send signals to several analog-to-digital converters, which convert the pressure readings into digital data that can subsequently be handled by these super-fast programmable devices known as FPGAs. These chips are extremely fast and dependable at performing the logical tasks required by the computer.

An ARINC 429 transceiver handles all communication between the controller and the rest of the plane’s equipment, delivering and receiving information such as altitude as well as destination elevation. It’s all managed by software, which employs a highly specialized algorithm to precisely modify the valve locations. The way it works is that when the plane ascends to higher altitudes, the pressure within the cabin gradually decreases, at no more than 200 feet per minute equivalent. When the plane descends, the process reverses and the pressure gradually rises again. When the plane lands, the valves fully open, allowing fresh air to enter.

One of the most brilliant features is that the valves themselves have redundancy built in, so even if one fails, the other can keep the pressure up to a safe level. There are also safety mechanisms that keep the air pressure from rising too high, which could put strain on the aircraft. Pneumatic actuators operate the valves by blowing air into them, much like a little balloon inside the valve, to balance the internal and external air pressures.

Every component in this system is designed to withstand the rigors of flight, including years of heat, cold, and turbulence, without ever failing. The development process was far more stringent than usual, with each line of code being scrutinized to ensure that it met the essential standards. There are even watchdog timers that perform a reset if the system ever becomes stuck.

[Source]

Boeing 777 Cabin Pressure Control System Teardown Reveals the Hidden Guardian of Your Flight

#Boeing #Cabin #Pressure #Control #System #Teardown #Reveals #Hidden #Guardian #Flight